In today’s global fast-charging market, simply stacking higher wattage is no longer a true competitive advantage. The real line between average suppliers and technology leaders lies in how well thermal management efficiency is balanced with deep protocol compatibility.

Through proprietary fast-charging chip development and a bottom-level power management architecture, AOVOLT addresses heat loss at the chip level, fundamentally solving the overheating challenges that plague compact high-power chargers. This enables global B2B buyers to source fast-charging solutions that truly deliver “original-manufacturer charging speed with low-temperature operation.”

For cross-border e-commerce sellers and brand owners, the pain point in selecting OEM/ODM partners has shifted from “Can they manufacture?” to “How do we minimize risk?”

Generic designs trigger price wars, excessive power consumption introduces safety hazards, and incomplete certifications lead to platform delistings—all of which erode margins.

AOVOLT’s core R&D team consists of senior power architecture engineers from Xiaomi, OPPO, and Vivo. Beyond hardware manufacturing, we help clients build durable technical and compliance barriers through patented industrial design and proprietary PCBA solutions—moats that competitors can’t easily cross.

The Hidden Enemy of Mini Fast Chargers: Understanding the Real Cause of Heat

In the mini fast charger category, increasing power density almost always comes at the cost of reduced thermal dissipation space. During sample evaluations, many B2B buyers focus only on the first 10 minutes of charging speed, while overlooking thermal saturation under sustained high load.

Why Conventional OEM Designs Fail to Solve Overheating

Most generic OEM factories rely on third-party reference chip solutions. To maintain broad compatibility, these solutions use conservative current allocation algorithms, resulting in several structural limitations:

-

Energy Conversion Loss

Low-grade inductors and capacitors convert approximately 10–15% of electrical energy into heat during AC/DC conversion. -

Lack of Power Factor Correction (PFC)

Simplified circuitry in compact designs increases harmonic distortion, raising overall component temperatures. -

Redundant Protocol Handshakes

Inability to precisely adjust voltage steps for different devices leads to unnecessary voltage drop losses during charging.

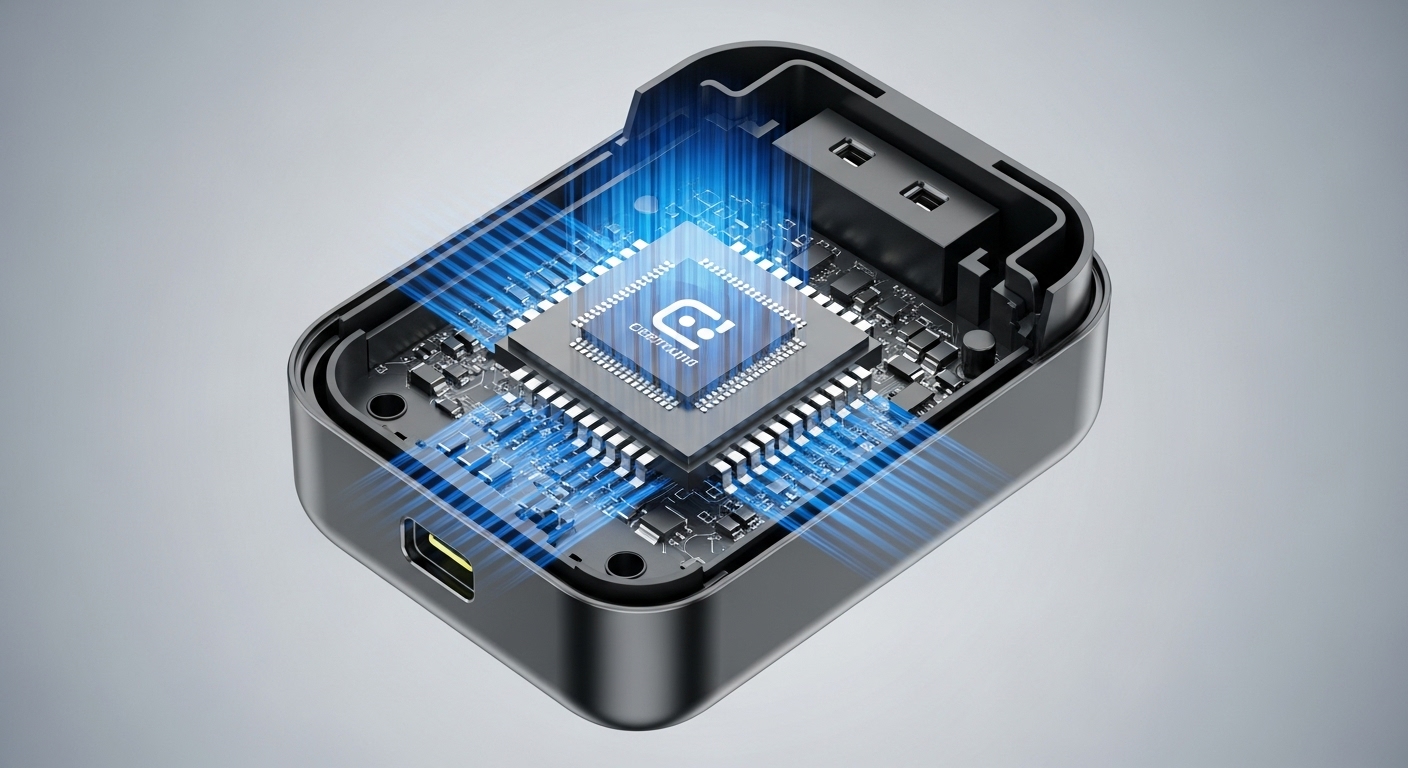

AOVOLT’s Low-Temperature Fast-Charging Architecture

Thanks to full vertical integration—from fast-charging chip design and PCBA development to tooling and final assembly—AOVOLT can monitor current curves at the microsecond level throughout the entire charging process.

-

Intelligent Synchronous Rectification

Conversion efficiency exceeds 93%, significantly reducing waste heat at the source. -

Proprietary High-Frequency Transformers

Custom magnetic components minimize electromagnetic loss during high-frequency switching. As a result, even after two hours at full load, AOVOLT mini chargers maintain a surface temperature of 45°C–50°C, well below the industry norm of 65°C.

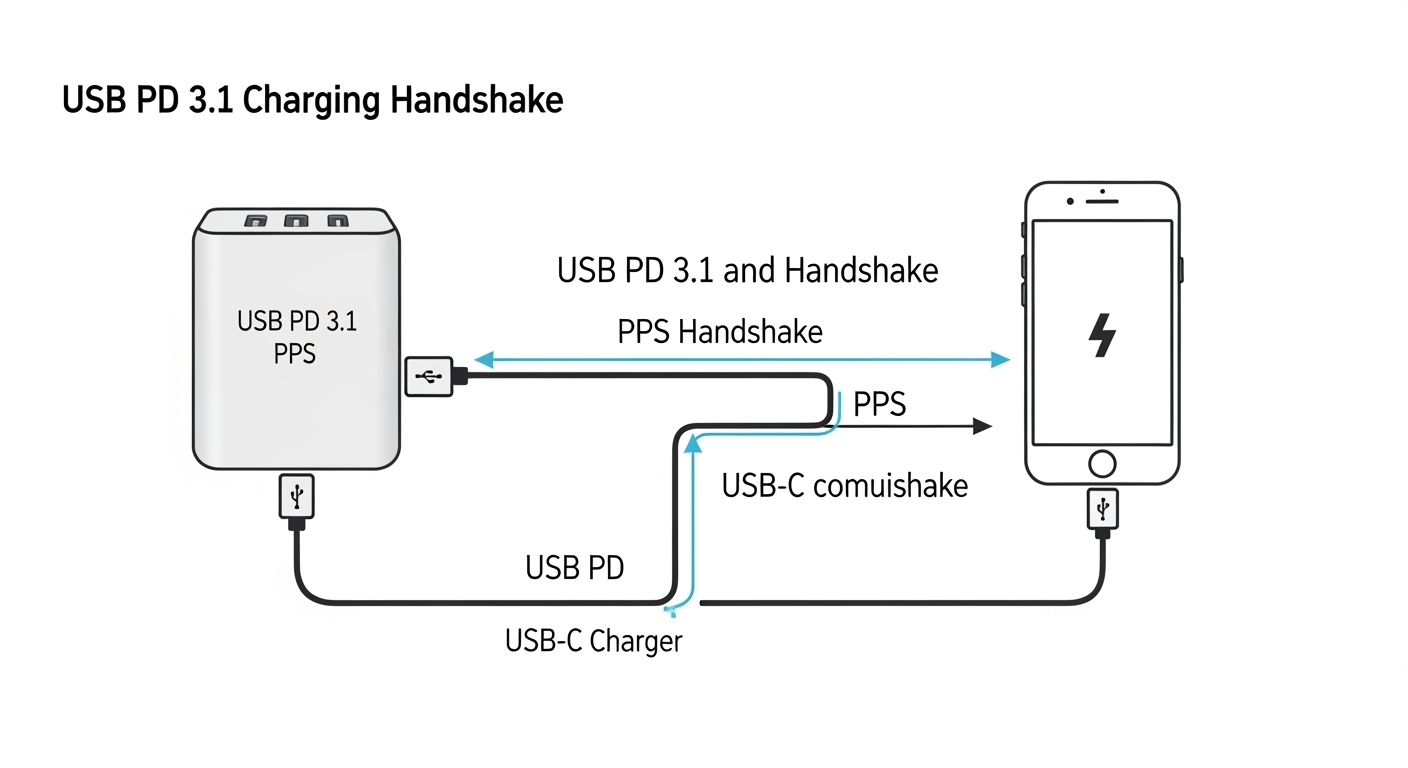

Protocol Compatibility and “Original-Manufacturer Speed”

One of the most common end-user complaints received by B2B clients is:

“Why does a 30W charger feel slow?”

In most cases, the issue isn’t insufficient power—it’s shallow protocol negotiation.

Deep-Level Decoding of PD 3.1 and PPS

Leveraging its deep roots in leading smartphone manufacturers, AOVOLT has re-engineered the Programmable Power Supply (PPS) protocol at the architectural level. Our proprietary PCBA precisely matches the original charging algorithms of iPhone, Samsung, Xiaomi, and other major brands. Fast charging chipsets: How to determine efficiency and safety?

Performance Comparison

| Technical Metric | Standard OEM Solutions | AOVOLT “Original-Speed” Solution |

|---|---|---|

| Peak Efficiency Duration | Only first 5–8 minutes, then throttles | Sustains peak power until 80% battery |

| Voltage Step Precision | 100 mV per step (standard PD) | 20 mV per step (precision tuning) |

| Multi-Device Compatibility | Protocol conflicts, frequent resets | Dynamic power allocation with device recognition |

| Standby Power Consumption | > 75 mW | < 30 mW (meets the strictest global efficiency standards) |

“Flexible Fast Charging” That Protects Battery Health

Speed alone isn’t the goal—device longevity matters.

Using AOVOLT’s proprietary intelligent current compensation technology, the charger delivers a smoother current curve during the trickle-charging phase. This reduces lithium plating and extends battery cycle life by 15–20%.

For brand owners, this translates directly into lower return rates and stronger customer loyalty.

Global Compliance and Safety Certifications: The Foundation of Cross-Border Trade

For large-volume B2B buyers—especially top sellers on platforms like Amazon and Wayfair—compliance is non-negotiable.

Non-certified power products risk customs seizures, regulatory penalties, and even permanent platform account bans.

Meeting Market Entry Requirements Worldwide

AOVOLT operates a strict quality control and in-house laboratory testing system to ensure every product meets major global regulatory standards before mass production.

-

Europe (CE / RoHS / ErP)

Optimized standby power consumption ensures compliance with EU energy-efficiency and environmental directives. -

North America (FCC / ETL)

Strict electromagnetic interference (EMI) control prevents disruption to Wi-Fi and other wireless devices in residential environments. -

Logistics & Transport Safety (UN38.3 / MSDS)

Power bank cells undergo extreme tests—including crush, puncture, and thermal cycling—to ensure absolute safety during air and sea transport.

Why Full Certification Lowers Total Procurement Cost

Some entry-level suppliers cut corners by using outdated or incomplete certifications. While this may reduce upfront pricing, it exposes buyers to serious legal and commercial risks.

AOVOLT provides one-stop Letter of Authorization (LOA) support, helping clients pass platform audits faster and reduce time-to-market by 4–6 weeks.

Building Differentiation: Patented Design and Brand Premium

In consumer electronics accessories, homogeneity equals price wars.

When search results display 100 identical white chargers, price becomes the only deciding factor.

Avoiding the Risks of Generic Designs

AOVOLT is committed to original design. We understand that differentiation is a core B2B requirement.

-

Exclusive Design Patents

Protects brand identity and shields products from malicious IP complaints. -

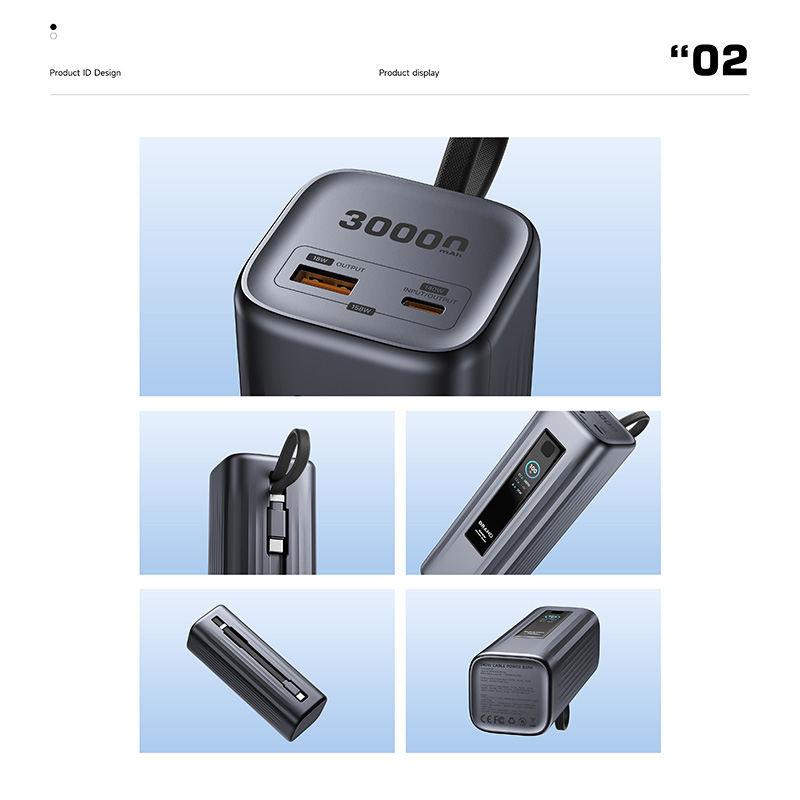

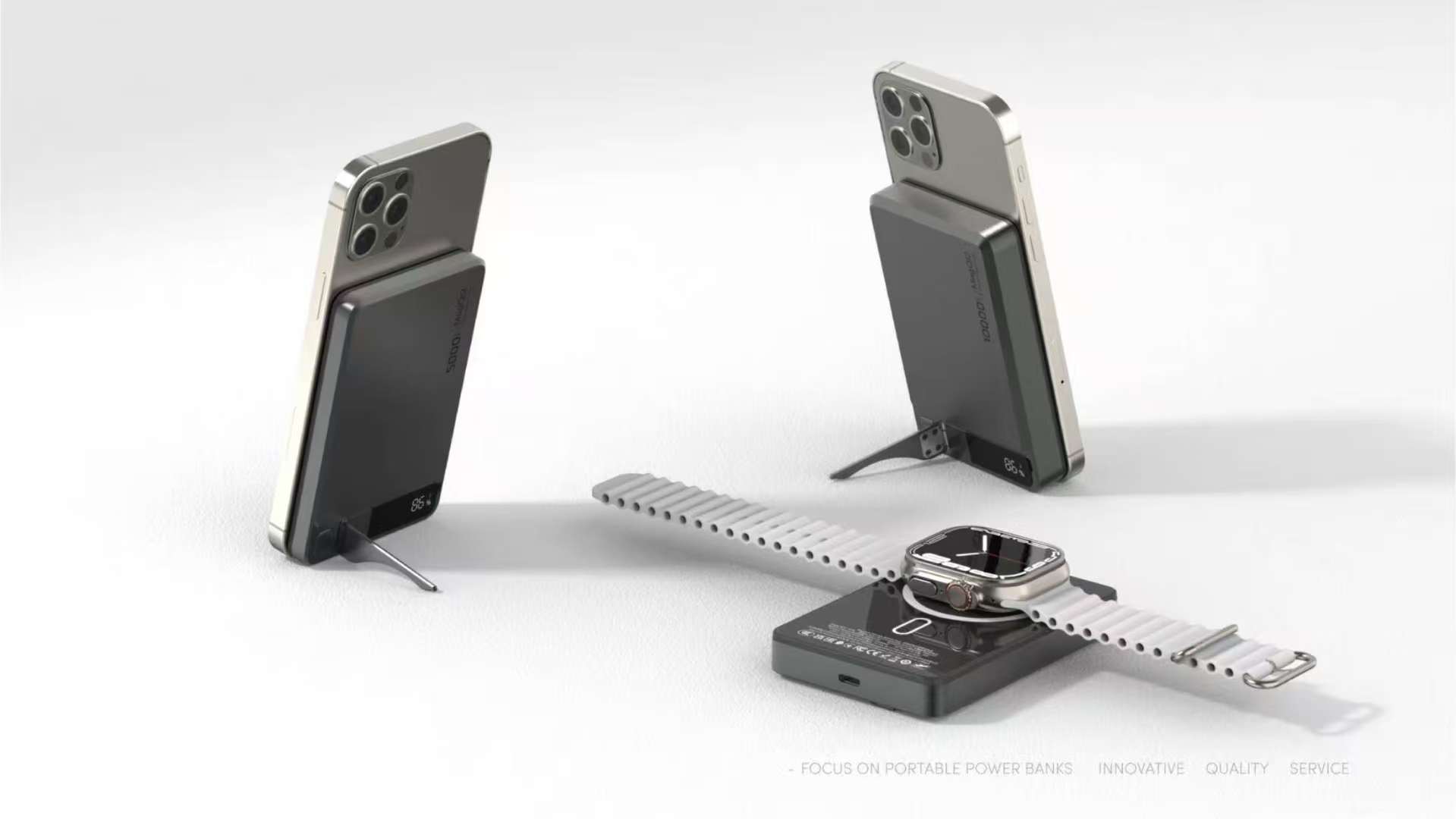

Structural Innovation

Examples include:-

Foldable prongs tested for 10,000 cycles without loosening

-

Ultra-slim GaN internal stacking structures

These breakthroughs are only possible through proprietary PCBA development.

-

Customization Enabled by Vertical Integration

With full control over chip design, PCBA development, tooling, and final assembly, AOVOLT can rapidly customize:

-

Housing materials

-

Indicator light logic

-

Port configurations

—all without compromising thermal management. This depth of customization is beyond the reach of traditional assembly-only factories.

What Truly Matters in B2B Decisions: Supply Chain Transparency and Capacity Assurance

In a rapidly evolving fast-charging landscape, choosing a partner is not just about current products—it’s about long-term R&D stability.

Digitally Managed ISO 9001–Certified Manufacturing

AOVOLT’s vertically integrated factory operates with ERP and MES systems, enabling full traceability from raw materials to final aging tests.

-

100% Full-Load Aging Tests

Every batch undergoes at least 4 hours of full-load cycling before shipment, ensuring low-temperature performance in real-world use. -

In-House Supply of Core Components

With proprietary PCBA and chip logic, AOVOLT maintains stronger resilience during industry-wide chip shortages, ensuring on-time delivery for large-volume clients.

Conclusion: Business Trust Built on Engineering Fundamentals

For brands seeking OEM/ODM partnerships, AOVOLT delivers more than chargers or power banks—it provides high-reliability power solutions backed by top-tier engineering experience.

By solving thermal challenges through in-house chips, avoiding commoditization with patented design, and eliminating compliance risks through global certification, AOVOLT empowers B2B clients to grow with confidence.

References: