What truly defines the quality of a fast-charging product is not its advertised wattage, but rather its internal fast-charging chipset solution and PCBA power management architecture. This “heart” of the system directly determines charging efficiency, thermal control, and long-term operational safety.

Choosing the wrong solution—even if it appears cost-effective in the short term—often leads to product recalls, safety incidents, and irreversible brand damage.

For global electronics brands and large-scale buyers, selecting the wrong OEM/ODM partner can result in product homogenization, safety recalls caused by overheating, and reputational damage due to poor device compatibility.

AOVOLT’s core R&D team is composed of senior engineers from leading smartphone brands such as Xiaomi and OPPO. We understand from first-hand experience that only through self-developed fast-charging ICs and power-management PCBA architectures can these systemic issues be eliminated at the source—ensuring every delivered product meets the demanding standards of “original manufacturer charging speed” and “low-temperature safety.”

Three “Invisible Killers” Hidden in Low-End Fast-Charging Solutions

In B2B procurement decisions, overlooking technical details is often where risk begins. Many low-cost, off-the-shelf fast-charging solutions on the market hide three fatal flaws that can quickly destroy product reputation.

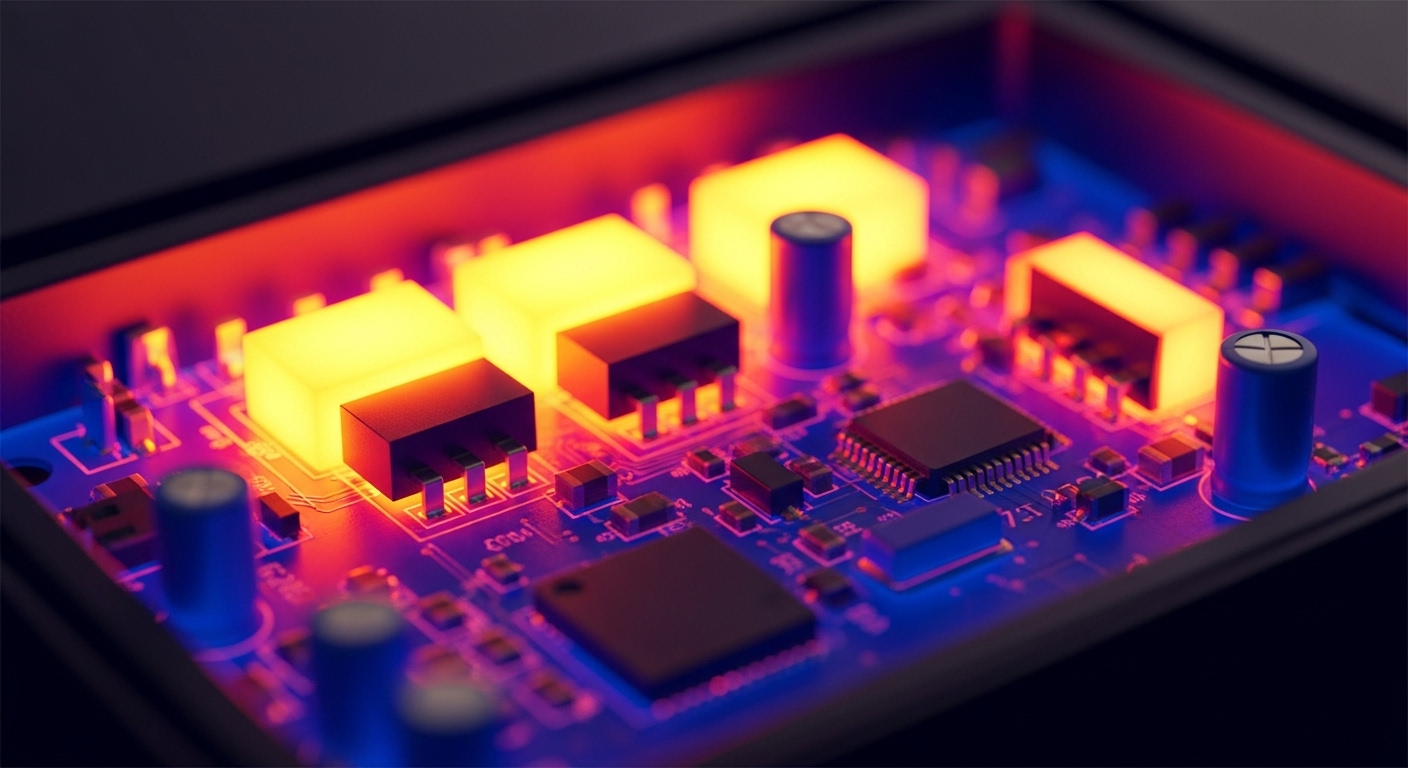

Killer #1: Thermal Management Failure — The Performance “Cliff Edge”

Heat generation is a direct indicator of energy loss. To reduce costs, low-end solutions often rely on low-efficiency MOSFETs and control ICs, which suffer from high switching and conduction losses. As a result, 15–20% or more of electrical energy is wasted as heat.

When internal temperatures exceed thermal thresholds, the chipset is forced to throttle frequency and output power, leading to:

-

Sharp drops in charging speed: The user experience collapses, making “fast charging” a false promise

-

Accelerated component aging: Long-term high-temperature operation drastically shortens the lifespan of capacitors and other key components

-

Casing safety risks: In extreme cases, enclosure deformation or melting may occur

Killer #2: Protocol Conflicts — The Compatibility Trap

Fast-charging protocol “handshakes” require extremely high precision and compatibility. Many generic solutions only provide basic support for PD or QC protocols, leading to frequent real-world failures:

-

Inability to trigger maximum power output: Poor recognition of proprietary brand protocols or PPS (Programmable Power Supply) profiles

-

Frequent charging interruptions: Unstable handshakes cause repeated disconnects and renegotiations

-

No support for emerging devices: Lack of compatibility with next-generation standards such as PD 3.1, making products obsolete upon launch

Killer #3: Excessive Ripple — A “Chronic Toxin” for Device Batteries

Ripple and noise levels are critical indicators of output current purity. Poor PCBA design and insufficient filtering capacitors introduce significant electrical noise into the output.

This unstable DC output acts like continuous micro-shocks to the batteries of smartphones, laptops, and other precision devices, resulting in:

-

Irreversible battery health degradation: Accelerated aging of internal electrochemical materials

-

Operational interference: Issues such as touchscreen malfunction during charging

Why One Wrong Procurement Decision Can Destroy a Brand

These technical shortcomings quickly translate into devastating commercial consequences. For B2B clients seeking to build a global brand reputation, partnering with a technically weak supplier is equivalent to placing the brand itself at risk.

-

High return rates and negative reviews: Consumers leave poor ratings on platforms like Amazon due to slow charging, overheating, or incompatibility—directly reducing listing visibility

-

Platform bans and legal exposure: Overheating-related incidents can lead to permanent marketplace bans and even class-action lawsuits

-

Brand value erosion: The market begins associating the brand with “cheap” and “unsafe”—a fatal blow for growth-stage brands

Choosing a fast-charging OEM/ODM partner is not a simple cost comparison. It is a strategic decision that determines brand credibility and long-term market viability.

A charger is not an accessory—it is the pacemaker of your brand reputation.

In-Depth Breakdown: Four Core Standards of a High-Quality Fast-Charging Chip Solution

At AOVOLT, we believe true fast-charging excellence is not about stacking wattage, but about maximizing energy conversion efficiency and thermal distribution.

For B2B buyers focused on long-term stability, a mature OEM/ODM fast-charging solution must meet the following technical benchmarks:

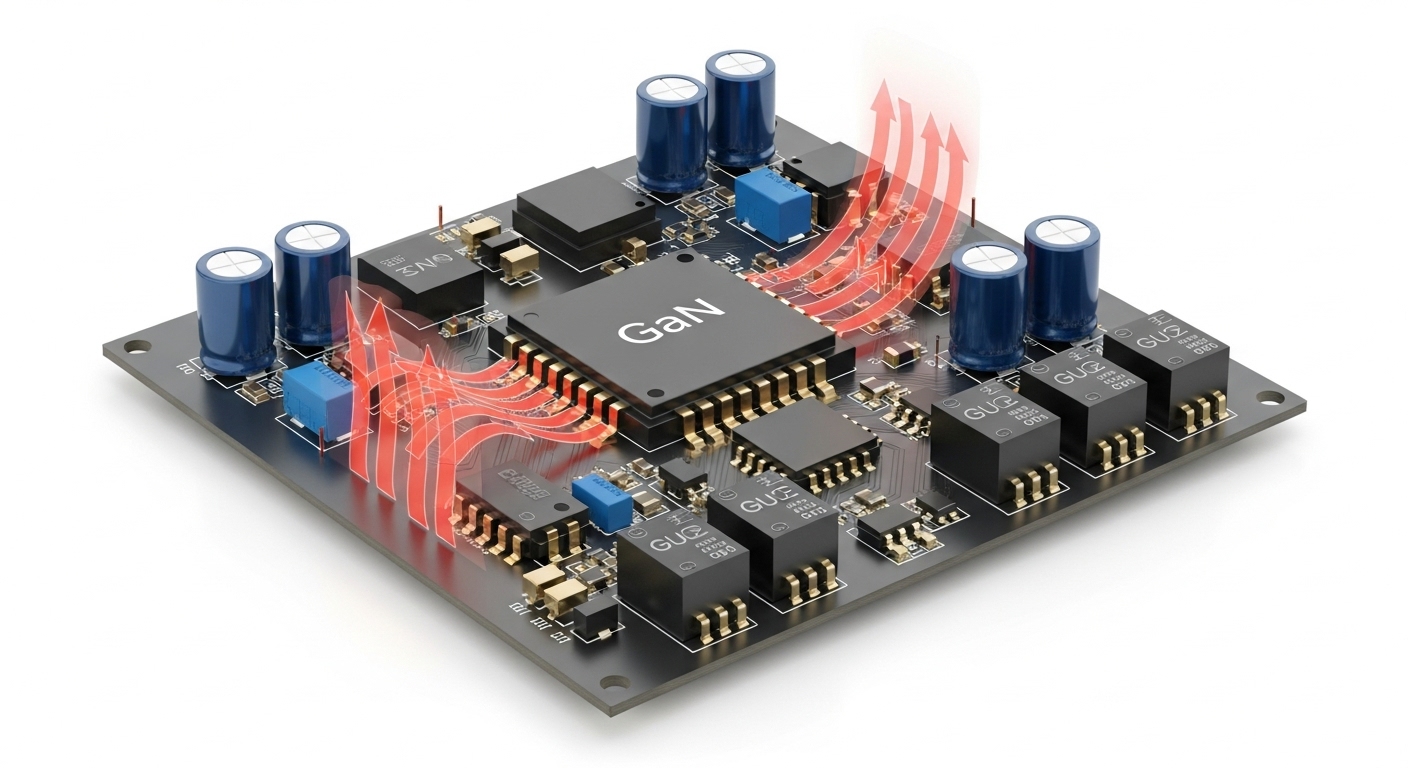

1. High-Efficiency Architecture: GaN Technology + Self-Developed ICs

Traditional silicon-based (Si) chips suffer significant efficiency losses when operating above 65W at high switching frequencies.

AOVOLT adopts third-generation GaN (Gallium Nitride) semiconductors combined with self-developed fast-charging ICs. By optimizing synchronous rectification (SR) and quasi-resonant (QR) control algorithms at the PCBA level, we achieve energy conversion efficiencies exceeding 92%.

This bottom-up customization ensures that even under full load, core component temperature rise is 10–15°C lower than industry averages, delivering genuine low-temperature, non-overheating performance.

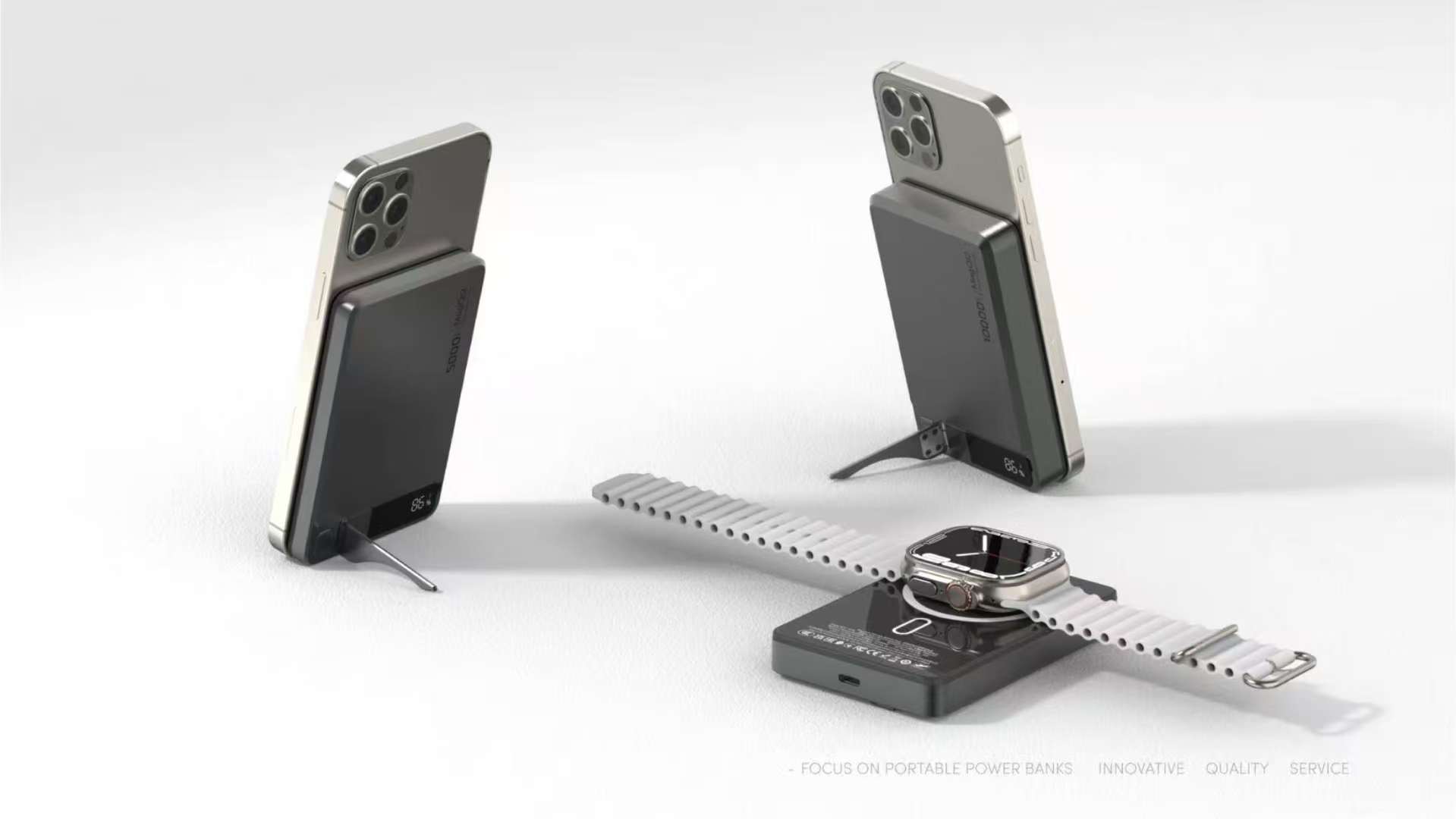

2. Intelligent Power Allocation (Dynamic Load Management)

Multi-port chargers (e.g., 2C1A desktop chargers) are the ultimate test of technical competence. Low-end solutions often cut power to all ports during device plug-in events, or distribute power unevenly—causing severe heat spikes. Learn about high-performance fast chargers: OEM guide to raw speed and thermal safety.

AOVOLT Solution:

-

Intelligent MCU continuously monitors real-time load on each port

-

Seamless, interruption-free power redistribution

Technical Advantage:

-

Each device receives optimal current based on real-time battery status

-

Delivers a true “Original Speed” charging experience, identical to brand OEM chargers

3. Technical Comparison: AOVOLT vs. Standard Market Solutions

The table below presents real-world test data based on a 65W GaN charger, illustrating how underlying chipset architecture directly impacts end-product performance:

| Performance Metric | AOVOLT Self-Developed Chipset | Generic Market Solution | B2B Procurement Impact |

|---|---|---|---|

| Conversion Efficiency | 92.5% – 94% | 85% – 88% | Higher efficiency = lower enclosure temperature |

| Full-Load Casing Temperature | ≤ 55°C (Low-temp safe) | ≥ 70°C (Uncomfortably hot) | Directly affects consumer complaint rates |

| Output Ripple | < 100mV (Ultra-clean output) | > 200mV (High noise) | Lower ripple = better battery protection |

| Protocol Compatibility | Full PD3.1 / PPS / Proprietary Protocols | Basic PD2.0 / PD3.0 | Determines full-brand fast-charge support |

| R&D Background | Tier-1 Brand Engineers (Xiaomi / OPPO) | Generic reference designs | Defines technical ceiling and differentiation |

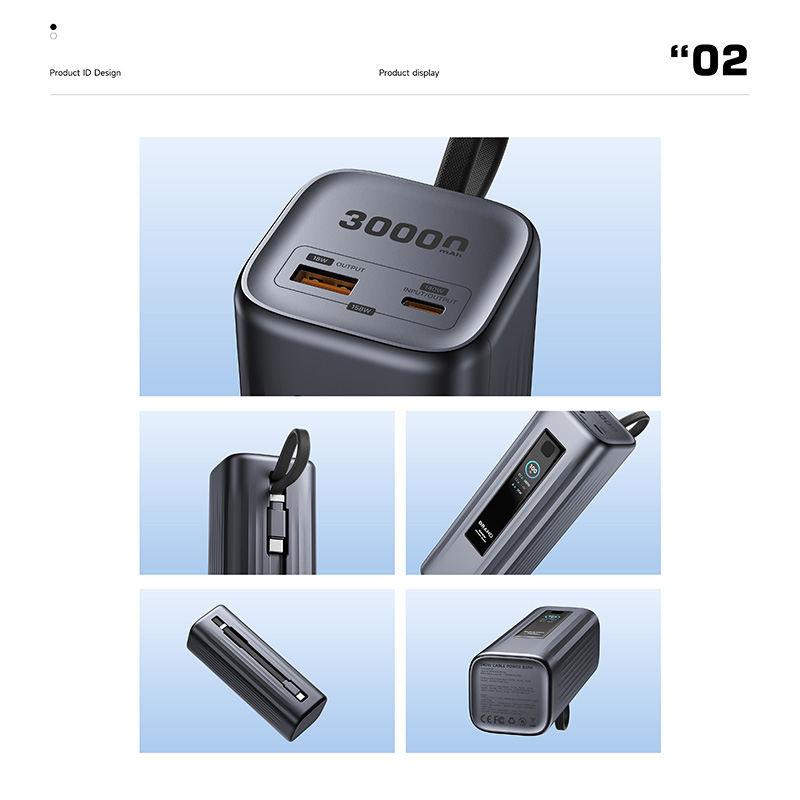

4. Patented Industrial Design & Internal Stacking — A Barrier to Price Wars

Thanks to AOVOLT’s vertically integrated capabilities—from chipset design and PCBA development to tooling and final packaging—we ensure every charger and power bank achieves both original-speed charging and low-temperature safety, with exceptional long-term stability.

More importantly, AOVOLT insists on patented industrial designs. On platforms like Amazon, eBay, and Lazada, generic public-mold products quickly fall into price wars and face serious infringement risks.

Our original designs provide customers with natural pricing power and built-in market protection.

Global Market Access: Certification & Compliance Are the Lifeline of B2B Trade

For cross-border sellers and large distributors, compliance is not just a technical requirement—it is a legal red line. Products lacking authoritative certifications risk total loss at customs clearance, warehouse intake, or marketplace listing stages.

Why AOVOLT Insists on “Full Certification Coverage”

As an ISO 9001-certified manufacturer, AOVOLT benchmarks all products against the world’s strictest safety standards from the R&D stage onward:

-

North America: FCC certification to ensure electromagnetic compatibility

-

Europe: CE and RoHS certifications for mandatory safety and environmental compliance

-

Battery Products: Full IEC 62133, MSDS, and UN38.3 reports to ensure absolute safety in sea and air transport

This comprehensive compliance framework allows B2B buyers to focus on market expansion—without worrying about delistings, seizures, or legal disputes.

Why AOVOLT Is the Optimal OEM/ODM Partner

In a saturated fast-charging market, AOVOLT builds three core competitive moats through vertical integration:

-

R&D DNA: Our core team comes from top-tier smartphone brands (Xiaomi, OPPO, Vivo), enabling us to apply OEM-level quality standards to every charger

-

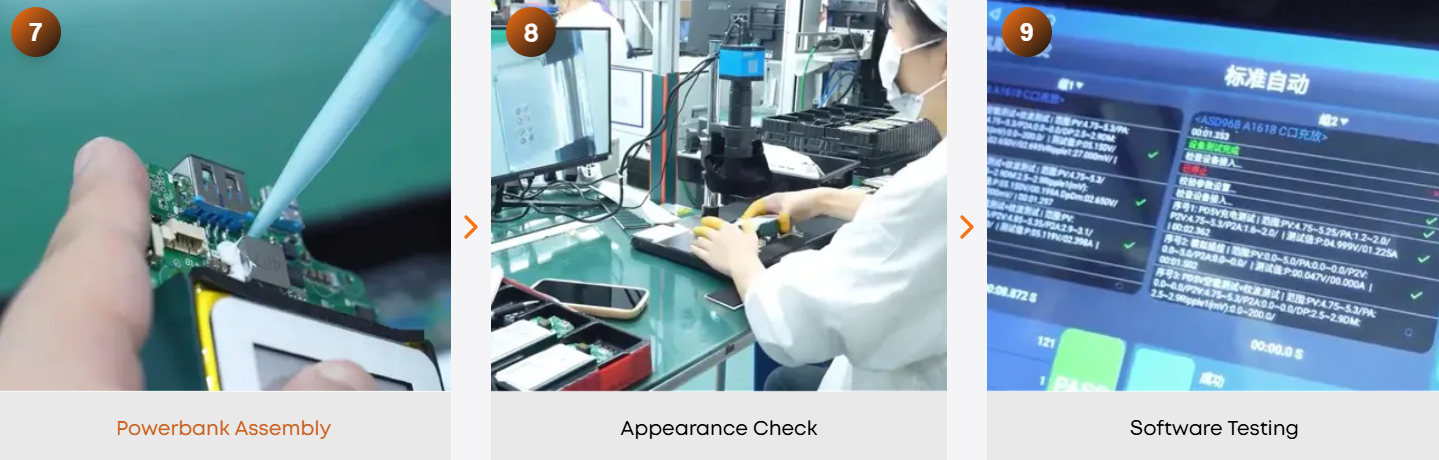

Supply Chain Control: From chip definition and SMT to final assembly, full-chain in-house control ensures both competitive BOM costs and precise lead-time management

-

Customization Flexibility: Whether PCBA modifications or brand-specific industrial design, AOVOLT delivers functional demos rapidly and transitions smoothly into mass production

Conclusion: Choose the “Heart,” Not Just the “Shell”

Fast-charging procurement is a game of technical trust. A truly capable supplier does more than deliver products—it delivers technical certainty.

Through self-developed chipsets, tier-1 R&D pedigree, and rigorous global certifications, AOVOLT transforms “fast charging efficiency” and “low-temperature safety” from marketing slogans into measurable data.

Looking for a high-stability, low-temperature fast-charging OEM/ODM partner?

AOVOLT is now opening customization channels for global partners.

Contact our senior application engineers today to receive exclusive PCBA solution recommendations and the latest product catalog.

References: