The core competitiveness of high-performance fast charging products is not defined by raw wattage numbers, but by their power density efficiency and thermal management performance under extreme operating conditions.

In B2B procurement decisions, ensuring that a charger delivers “original manufacturer–level charging speed” (Original Speed) while maintaining low operating temperature under heavy load (No Overheating) is the fundamental logic behind reducing after-sales risk and enhancing brand premium value.

For global electronics wholesalers and cross-border e-commerce sellers, sourcing low-quality fast charging solutions carries extremely high hidden costs. Thermal runaway can lead to accelerated battery degradation, enclosure deformation or melting, and even safety incidents. These issues not only result in high return rates, but may also trigger legal disputes or platform bans in target markets.

The AOVOLT core R&D team consists of senior power engineers from leading smartphone brands such as Xiaomi, OPPO, and Vivo. We clearly understand that only by developing proprietary fast-charging chips and optimizing power-management PCBA architectures—addressing thermal loss from the physical structure and algorithmic foundation—can a true technical moat be built for B2B customers.

1. Identifying the “Fast Charging Trap”: Why Do High-Performance Chargers Often Carry Safety Risks?

In the OEM market, many suppliers pursue low costs by adopting generic, off-the-shelf reference designs. While these solutions may briefly reach their rated power, they lack precise control over transient response and ripple under dynamic loads, causing large amounts of energy to dissipate as heat during power conversion.

Key Pain Point Analysis

-

Low Conversion Efficiency

Every 1% drop in efficiency in a charger above 65W results in several additional watts of heat accumulating inside a compact enclosure. -

Insufficient Component Derating

Low-end solutions often use capacitors and MOSFETs rated only marginally above minimum requirements, making them highly vulnerable to breakdown under voltage fluctuations or high ambient temperatures. -

Excessive Ripple & Noise

Poor PCBA designs with excessive output ripple can interfere with touchscreen responsiveness. Long-term exposure causes irreversible damage to battery cells in connected devices.

Comparison of Standard OEM Solutions vs. AOVOLT Professional-Grade Solutions

| Evaluation Dimension | Standard Market OEM Solution | AOVOLT “Original-Speed” Professional Solution | Impact on Procurement Decisions |

|---|---|---|---|

| Circuit Topology | Traditional Flyback | High-Frequency QR / ACF + Synchronous Rectification | Determines baseline conversion efficiency |

| Core Controller | Third-party generic controller | Proprietary customized fast-charging chip | Directly affects protocol handshake speed and accuracy |

| Average Efficiency | 85%–88% | 92%–94% (GaN Series) | Higher efficiency = lower heat rise & longer lifespan |

| No-Load Power Loss | < 150 mW | < 75 mW | Meets higher-tier energy efficiency regulations |

| Thermal Control Logic | Hardware cutoff at critical temperature | Intelligent AI-based dynamic frequency throttling | Maintains continuous output while ensuring safety |

2. Core Technology Review: Achieving the Balance Between “Original Speed” and “Low-Temperature Safety”

During factory audits or sample evaluations, B2B buyers should focus on a supplier’s R&D depth. Thanks to AOVOLT’s vertically integrated capabilities—from fast-charging chip design and PCBA development to tooling and final packaging—we ensure every charger and power bank delivers original-speed charging while remaining cool under load, with outstanding safety and performance stability.

Deep R&D Credentials: The Value of Tier-1 Engineering Teams

AOVOLT’s R&D team has over 10 years of experience serving top-tier smartphone brands. We do not simply assemble components—we optimize from the protocol stack level. This allows seamless compatibility with PD 3.1, PPS, QC 5.0, and other fast-charging standards, precisely matching voltage and current curves during device handshake to minimize energy loss.

Technical Path to “Cool Operation Without Overheating”

-

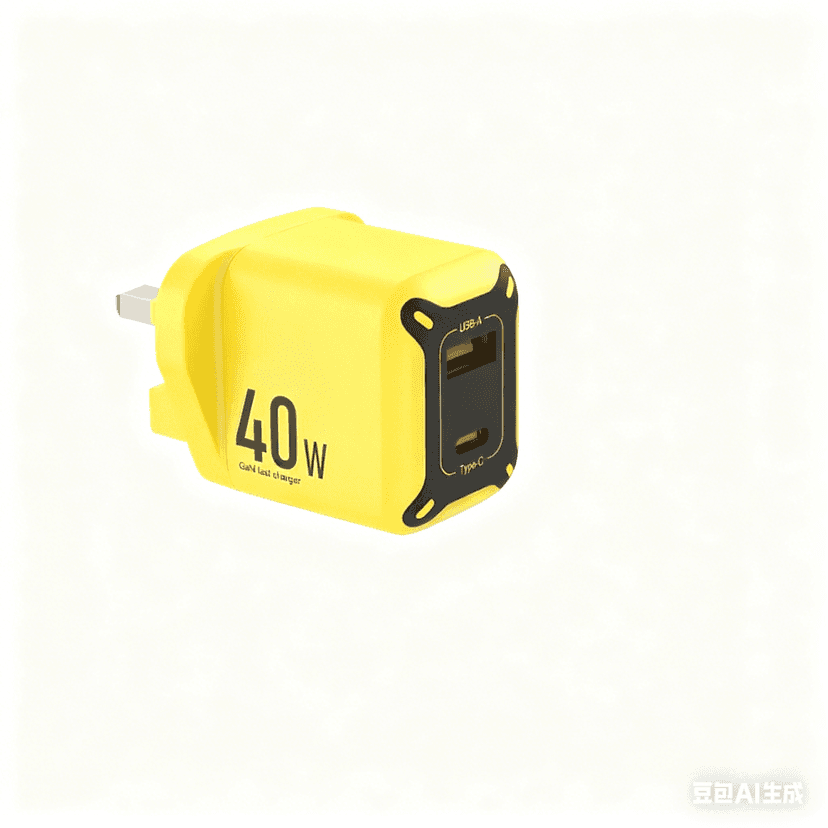

Third-Generation Gallium Nitride (GaN III) Technology

By using higher-frequency GaN power devices with lower on-resistance and proprietary driver circuits, switching losses are reduced by more than 30%. -

Multi-Layer Thermal PCB Design

The internal PCBA uses 2oz thick copper layers combined with high-thermal-conductivity potting materials, rapidly transferring heat from core components to the enclosure and preventing internal hot spots. -

Proprietary Fast-Charging Chip

Compared with generic controllers, AOVOLT’s chip integrates advanced load-sensing logic. When the device enters trickle-charging mode, the chip instantly adjusts duty cycles to prevent overshoot and unnecessary heat generation.

This level of control over foundational technology directly translates into commercial advantages for B2B customers: lower defect rates, better end-user reviews, and a reputation for high performance with exceptional stability in competitive markets.

3. Global Certifications & Compliance: The “Protective Shield” of Cross-Border Trade

In global B2B trade, certification compliance is not just a legal requirement—it is the foundational proof of product quality. Because chargers involve high-voltage power conversion, uncertified products face a high risk of customs seizure, as well as delisting or account suspension on platforms such as Amazon and Walmart.

Commercial Interpretation of Key Certifications

-

Safety & EMC (CE / FCC / RoHS)

These are entry tickets to the EU and North American markets. AOVOLT products strictly comply, ensuring minimal electromagnetic interference and environmentally compliant materials—reducing policy-driven trade risks. -

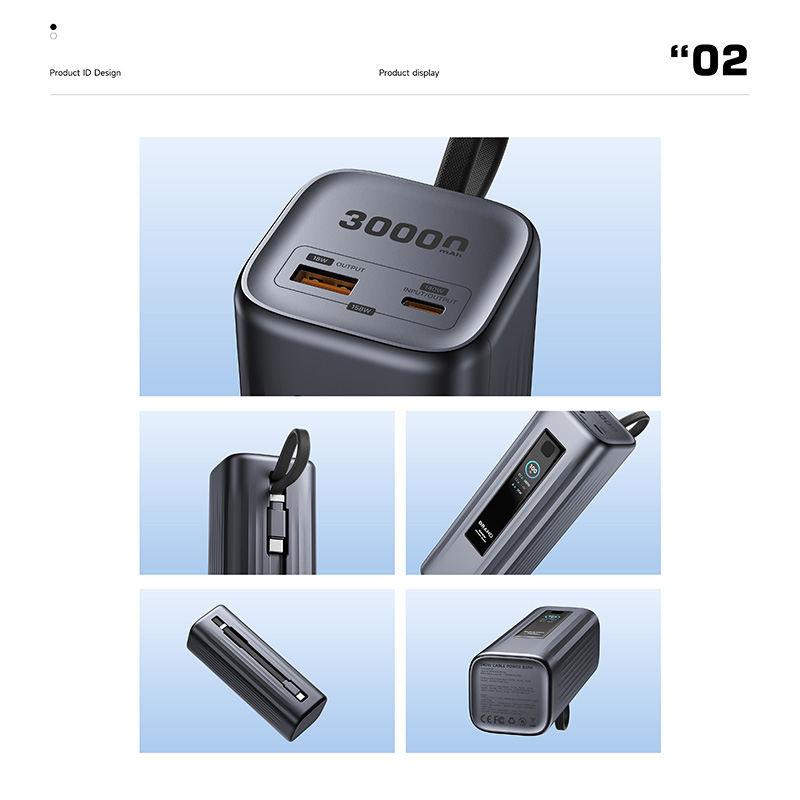

Battery & Power Bank Compliance (IEC 62133 / MSDS / UN38.3)

Power banks fall under Class 9 Dangerous Goods, with strict logistics restrictions. By passing UN38.3 drop, crush, and thermal shock tests and providing complete MSDS documentation, AOVOLT ensures legal global air and sea transportation. -

Design Patents

Generic public molds dominate the market, posing serious risks to brand-focused B2B buyers. AOVOLT insists on original designs and global design patent filings, helping customers avoid IP disputes related to look-alike products.

Required Certifications by Market

| Target Market | Required Certifications | Risks Avoided by Buyers | AOVOLT Support |

|---|---|---|---|

| European Union | CE, RoHS, ErP | Customs seizure, environmental fines, standby power bans | Full CE compliance, latest ErP standards |

| United States | FCC, UL/ETL (recommended) | EMI litigation, insurance claim denial | FCC Part 15 compliant, UL-ready PCBA design |

| Global Transport | UN38.3, MSDS | Airline refusal, in-transit combustion risks | Updated annual test reports for fast shipping |

| All Platforms | Design Patent Certificates | Malicious complaints, IP takedowns | Private molds with patent authorization |

4. Vertically Integrated Manufacturing: A Closed Quality Loop from Lab to ISO 9001 Factory

A common B2B pain point is “sample quality differs from mass production.” Many suppliers outsource R&D and manufacturing, resulting in long supply chains and fragmented quality control.

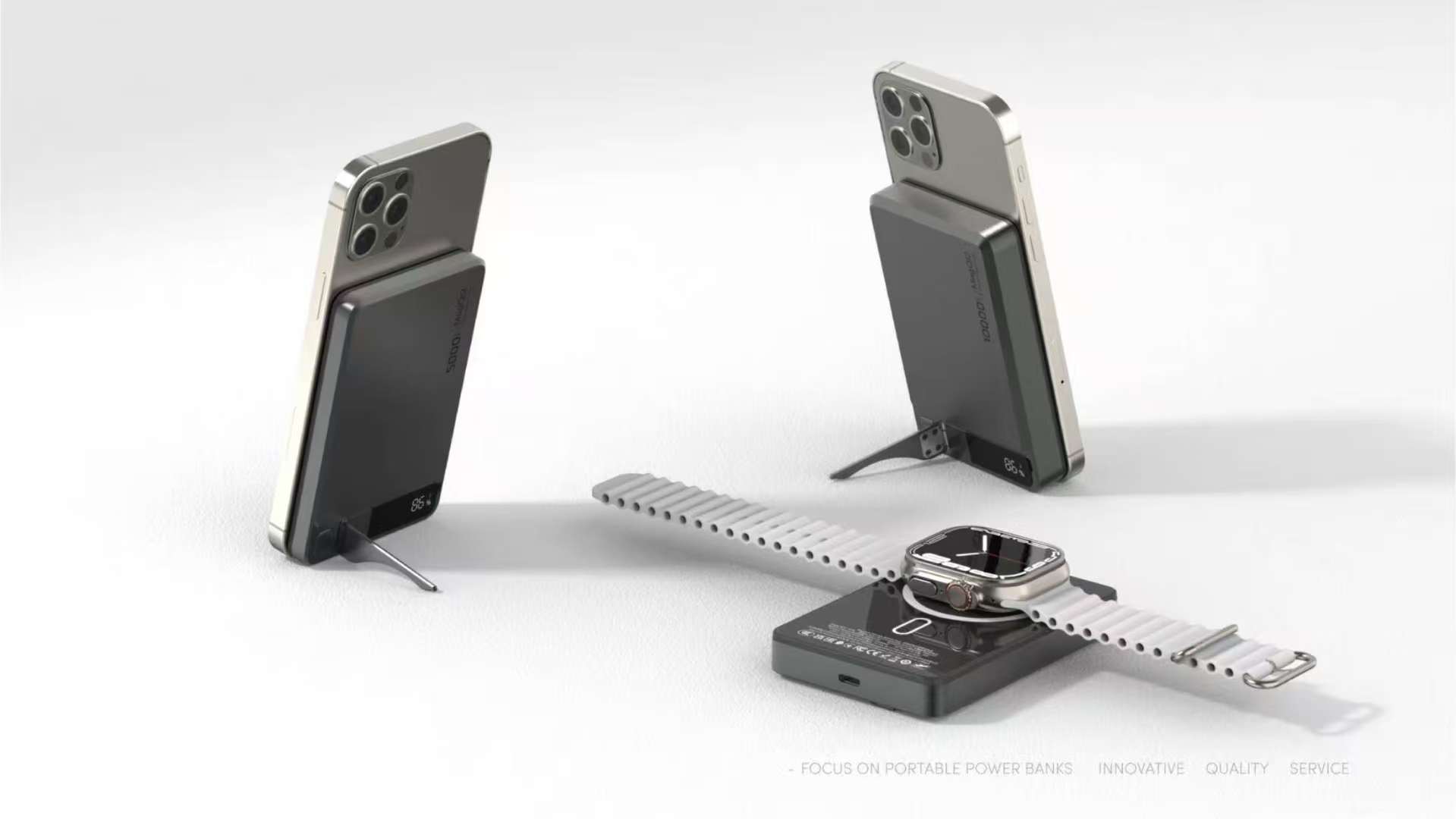

Thanks to AOVOLT’s full vertical integration—from chip design and PCBA development to tooling and packaging—we guarantee that every unit maintains original-speed performance with low-temperature operation, offering exceptional safety and stability. This model provides buyers with unmatched transparency and controllability.

Four Guarantees for B2B Delivery

-

Quality Consistency

Operating under ISO 9001, all self-developed PCBAs undergo 100% process inspection, from SMT to final assembly—allowing defects to be intercepted earlier than with outsourced PCBAs. -

Shorter ODM Development Cycles

When customers request specific power allocations (e.g., USB-C 100W + USB-A 18W), our former tier-1 engineers can directly modify chip-level code—without waiting for third-party chipset vendors. -

Cost Efficiency

Vertical integration eliminates intermediary margins. Direct control of chip and PCBA costs allows AOVOLT to offer more competitive profit margins at the same high-performance level. -

Strict Aging Test Standards

Every production batch undergoes 100% full-load aging tests (4–8 hours) under simulated high-temperature and high-humidity conditions—ensuring lab promises translate into real-world reliability.

5. Decision Guide: A Practical Checklist for Selecting High-Quality OEM Partners

Based on 15 years of industry experience, B2B buyers should conduct a “deep-dive audit” using the following checklist before placing final orders:

-

R&D Depth Assessment

Can the supplier modify PDO (Power Data Object) parameters during PD protocol handshakes? If only cosmetic changes are possible, they are a basic assembler—not a technical partner. -

Thermal Performance Verification

Request thermal imaging reports for at least 1 hour of full-power operation. Check whether surface temperature rise complies with IEC 62368-1. -

Compatibility Test Database

Leading suppliers maintain comprehensive test labs covering Apple, Samsung, Xiaomi, Lenovo, and other major brands—ensuring no black-screen charging or intermittent reconnection issues. -

Supply Chain Resilience

Verify sourcing of core power components (GaN or silicon MOSFETs). AOVOLT maintains long-term strategic partnerships with top global semiconductor suppliers, ensuring stable supply even during chip shortages.

Conclusion: Value Collaboration Beyond the Product

In today’s rapidly evolving fast-charging landscape, B2B procurement is no longer a simple transaction—it is a deep alignment of technology, safety, and compliance.

AOVOLT is not merely delivering charging tools with original-manufacturer speed. We provide a complete business solution built around low return rates, high premium potential, and zero compliance risk. Through proprietary fast-charging chips, elite engineering teams, and disciplined vertical manufacturing, we help partners build durable competitive barriers in the fast-charging market.

Call to Action

Looking for a fast-charging OEM/ODM partner with proprietary technology and global compliance strength?

Contact AOVOLT’s technical marketing specialists today to receive the latest product roadmap and market-specific technical whitepapers. We offer free sample testing and design patent authorization consulting to help your brand achieve true differentiation.

References:

USB Power Delivery 3.1 Specification

IEC 62368-1 Audio/video, Information and Communication Technology Equipment