In the global power electronics market of 2026, simple assembly-based manufacturing has lost its edge. True leadership in fast charging now depends on deep, in-house PCBA circuit engineering and precise tuning of complex protocols such as PD 3.1 and PPS. This is the only path to achieving “original-manufacturer-level charging speed” while ensuring long-term device reliability.

For global B2B buyers and cross-border brands, recurring issues—such as protocol compatibility failures, high return rates caused by overheating, and homogenized product designs triggering infringement risks on platforms like Amazon—have become the core obstacles to sustainable growth.

Backed by a senior engineering team from Xiaomi, OPPO, and Vivo, AOVOLT addresses these industry-wide problems at their root. Through self-developed intelligent fast-charging chips and power management architectures, AOVOLT eliminates chronic third-party fast-charging issues such as inflated power ratings and thermal throttling—not by marketing claims, but by engineering.

Hidden Risks in the Fast-Charging Market: Why Most OEM Products Fail to Deliver “Original-Speed” Charging

A major misconception dominates today’s fast-charging OEM market:

“Buying a generic GaN chipset equals high-performance charging.”

This public-board assembly model is precisely why end users continue to complain about slow charging and excessive heat.

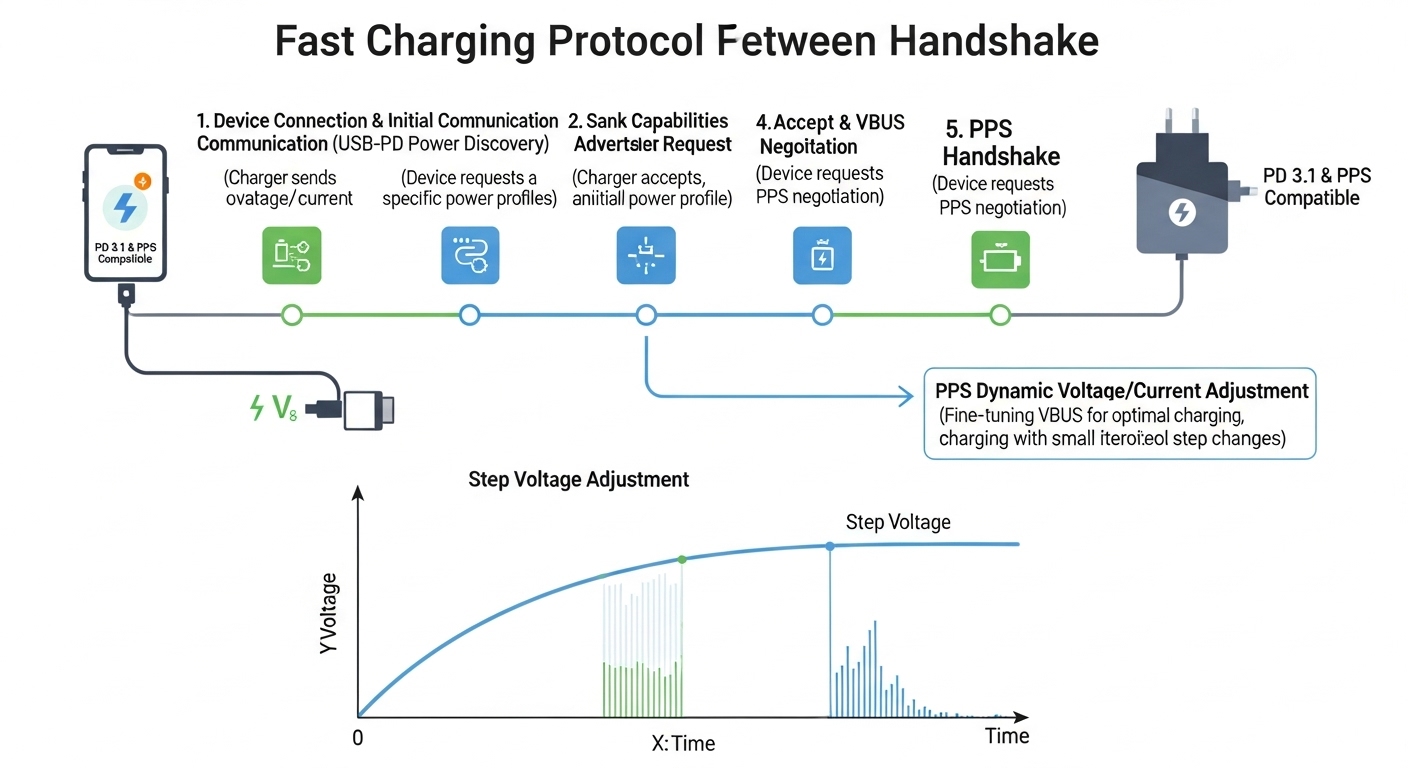

Protocol Handshake at the Circuit Level — Why Generic PCBA Causes Power Drop-Off

Most generic PCBA solutions rely on standardized protocol chips with slow firmware update cycles, making them incapable of fully matching the PPS (Programmable Power Supply) requirements of flagship devices such as the iPhone 15/16 series or Samsung Galaxy S24/S25. High-performance fast-charging PCBA: reduce BOM cost and improve efficiency.

-

Low Voltage-Step Precision

Coarse step-voltage control during protocol handshakes leads to frequent power drop-offs. As a result, average charging power falls far below advertised peak output. -

Compatibility Gaps

When new devices enter the market, manufacturers without in-house firmware control cannot resolve protocol conflicts—causing products to become obsolete upon launch.

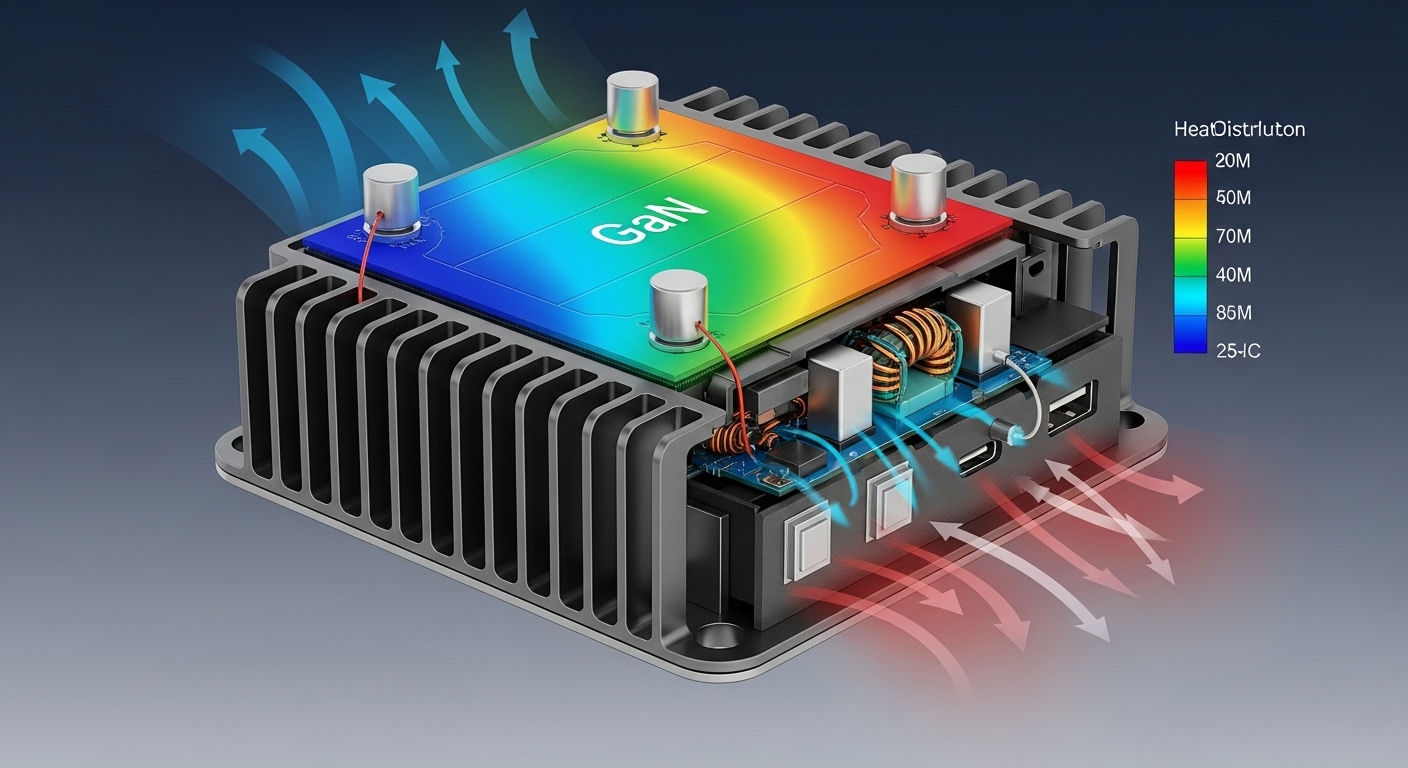

Thermal Management Challenges — Solving Heat Without Increasing Size

Compact desktop chargers and GaN fast chargers in 2026 operate at extremely high power densities. Most factories resort to adding thermal pads or reducing output current, directly sacrificing user experience.

-

Ripple Voltage Control

Poor PCBA ripple suppression not only increases thermal loss but also accelerates battery degradation. -

Efficiency Bottlenecks

AOVOLT’s self-developed circuitry optimizes synchronous rectification logic, achieving over 94% power conversion efficiency, reducing heat at its source rather than dissipating it afterward.

Table 1: Generic Assembly vs. AOVOLT In-House PCBA Performance Comparison

| Key Metric | Common OEM Assembly | AOVOLT In-House Engineering | B2B Value Impact |

|---|---|---|---|

| Protocol Compatibility | Standard PD only, limited PPS | Deep PD 3.1 / PPS + proprietary phone protocols | Fewer compatibility complaints |

| Voltage Step Precision | 100–200 mV | 20 mV (Ultra-Precise) | Extended battery lifespan |

| Full-Load Efficiency | 88%–90% | 94%–95.5% | Lower enclosure temperature |

| Ripple Control | <150 mV | <50 mV | Factory-grade clean power output |

| Firmware Updates | None (chip-locked) | Custom firmware iteration | Longer product lifecycle |

AOVOLT’s Engineering Boundary: Rebuilding the Charging Experience from a Tier-One Smartphone Perspective

AOVOLT’s core advantage lies in its engineering-driven culture. We believe a great charger is not just a power delivery device—it is an extension of the smartphone’s power management system.

From Xiaomi, OPPO, Vivo to AOVOLT — Bringing Tier-One Smartphone Standards to Third-Party Accessories

In top-tier smartphone R&D systems, safety and efficiency are non-negotiable red lines. AOVOLT applies these same validation standards to OEM/ODM manufacturing.

-

2,000+ Hours of Extreme Aging Tests

Unlike industry-standard 2–4 hour sampling tests, our PCBAs undergo full-load cyclic aging to ensure stability in high-temperature regions such as Southeast Asia and the Middle East. -

Multi-Layer Safety Logic

Beyond basic OVP/OCP, our proprietary Intelligent Dynamic Power Allocation algorithm rebalances output across ports within milliseconds, preventing disconnects or system crashes.

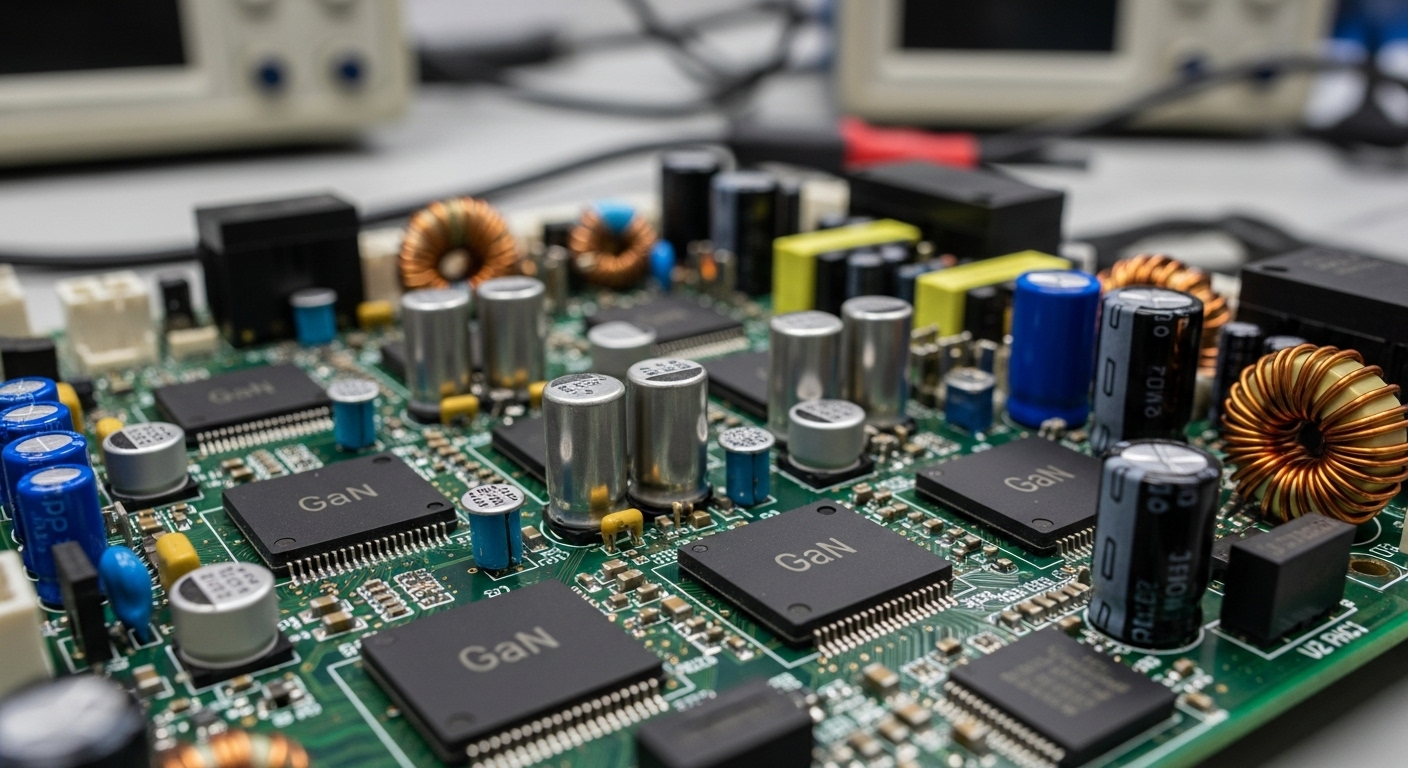

In-House PCBA Development — Absolute Control Over the “Charging Brain”

We do not rely on chip vendors’ reference designs. AOVOLT’s power management architecture is built on fully self-designed PCBA layouts.

-

Premium Component Selection

Automotive-grade capacitors and low-loss, high-frequency inductors ensure long-term reliability under continuous high-frequency operation. -

Custom Charging Curves

For different power bank capacities, we optimize a three-stage charging curve, reducing 0–80% charging time by approximately 30% without compromising safety.

“Low Temperature Without Power Sacrifice” — Cooling Architecture by Design

At AOVOLT, low temperature is not achieved by limiting power—it is the natural result of high efficiency.

-

Active Thermal Balancing

Multiple temperature sensors across PCBA phases dynamically fine-tune switching frequency in real time. -

SiP (System-in-Package) Integration

In high-end custom models, SiP packaging reduces parasitic inductance, further improving efficiency and enabling ultra-compact designs demanded by cross-border e-commerce buyers.

Solving B2B Pain Points: Patent-Protected Design and Platform Risk Mitigation

In 2026, visual homogenization has become the number-one profit killer in both cross-border e-commerce and offline distribution. For Amazon sellers and brand distributors, public-mold products invite price wars and infringement takedowns.

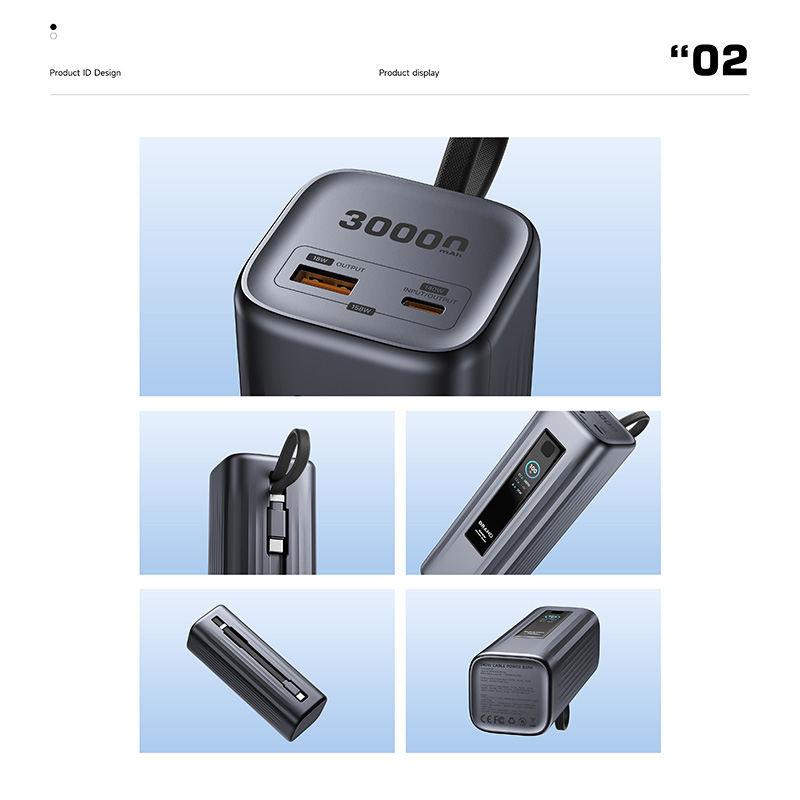

Patented Industrial Design — The First Line of Listing Protection

Every core AOVOLT product carries independent design patents.

-

Infringement Risk Avoidance

Our legal and design teams conduct exhaustive prior-art searches to eliminate appearance-based complaints. -

Private-Mold Exclusivity

Partners can obtain exclusive visual authorization within their segment, maintaining pricing power and brand recognition.

Where Aesthetics Meet Function

AOVOLT follows a Tech-Aesthetic design philosophy.

-

Advanced Materials

UL94-V0 flame-retardant PC combined with fine sandblasting or vacuum coating enhances durability and tactile quality. -

Compact Architecture

Thanks to dense in-house PCBA layouts, our multi-port desktop chargers are 15–20% smaller than comparable products—perfectly aligned with minimalist workspace trends.

Compliance and Reliability: Going Beyond Basic CE and FCC

In B2B trade, certifications are not paperwork—they are market access passports. AOVOLT operates under ISO 9001 quality systems, with products engineered redundantly to meet regional standards.

Rigorous Quality Control and Global Certification Framework

We design to exceed minimum thresholds, using IEC 62368-1 as our baseline standard.

Table 2: AOVOLT Global Market Certifications and Technical Enhancements

| Market | Core Certifications | Additional AOVOLT Standards | B2B Significance |

|---|---|---|---|

| North America | FCC, UL / ETL | UL94-V0 flame-retardant housing | Reduced fire insurance and legal risk |

| Europe | CE, RoHS, ErP | Standby power < 0.075W | Sustainability and brand credibility |

| Global | IEC 62368-1 | 6kV surge protection | Fewer weather-related failures |

| Japan / Korea | PSE, KC | Grid-frequency-optimized circuits | Silent long-term operation |

| Power Banks | MSDS, UN38.3 | 100% X-ray cell inspection | Safe air & sea transport |

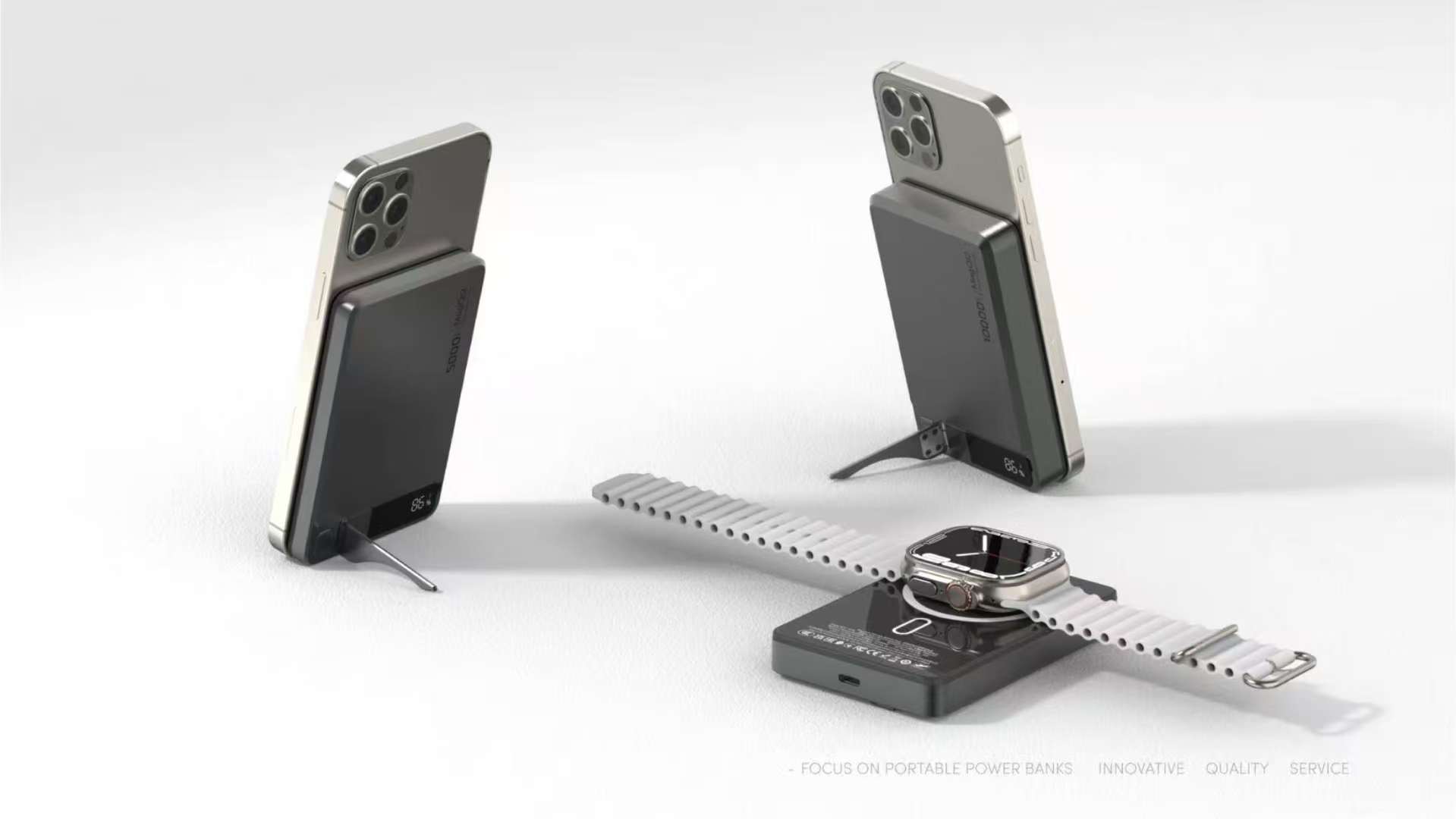

Power Bank Safety — Why We Are “Obsessive” About Battery Cells

In 2026, high-energy-density battery safety is under intense scrutiny. AOVOLT power banks use automotive-grade Li-polymer or LiFePO₄ cells.

-

Core Cell Protection (PTC/NTC)

Each pack features independent thermal monitoring. Any anomaly triggers millisecond-level BMS cutoff. -

Drop-Resistant Structure

Shock-absorbing internal brackets prevent compression-induced short circuits during accidental drops.

Partnership Model: From Concept to Global Distribution

As a vertically integrated manufacturer, AOVOLT delivers not just products—but end-to-end execution.

Flexible OEM / ODM Solutions

For high-growth electronics brands, AOVOLT provides full lifecycle support:

-

Product Definition

Power allocation strategies tailored to specific markets (e.g., North American gaming vs. European business users). -

Rapid Prototyping

Leveraging our PCBA library, prototype development cycles are reduced to 4–6 weeks. -

Retail-Ready Packaging

Eco-friendly designs compliant with global retail standards.

Our Commitment — Delivering “Original-Speed” Charging to Your End Users

AOVOLT remains firmly engineer-driven. We understand that B2B buyers are purchasing more than chargers—they are buying end-user trust. By eliminating heat, optimizing protocols, and protecting design IP, we help you build real brand loyalty in a crowded fast-charging market.

Conclusion: Your Brand Deserves Engineering Excellence, Not Just a Production Line

The competitive landscape of 2026 no longer tolerates trial-and-error manufacturing. Choosing an R&D partner with Xiaomi, OPPO, and Vivo engineering DNA means your products are born with the technical foundation to challenge industry giants.

AOVOLT is committed to transforming cutting-edge power electronics into stable, safe, and highly competitive fast-charging solutions.

Let’s redefine the charging experience—and power your global growth with real engineering strength.

References: