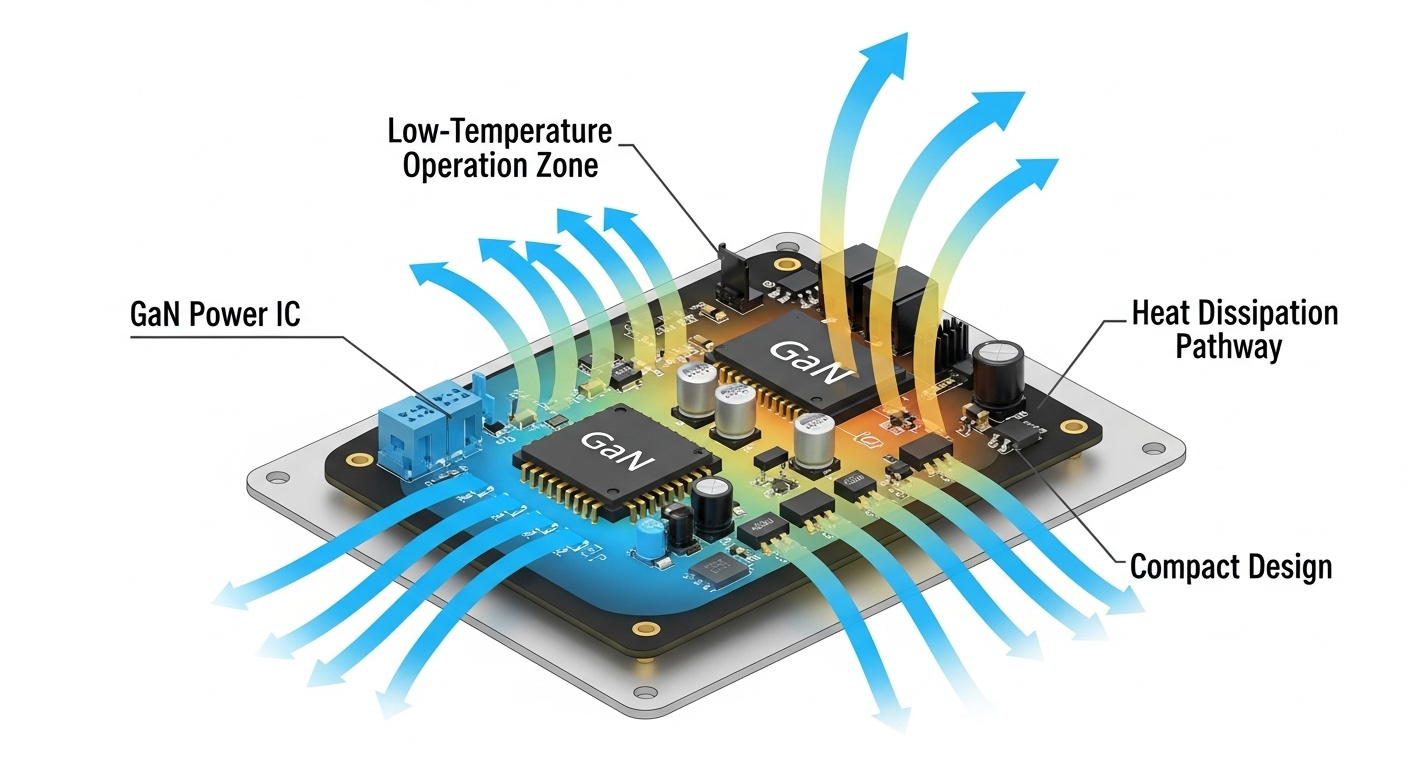

In B2B procurement and development of fast-charging products, high-performance PCBA solutions are the core engine for optimizing total cost of ownership (TCO). By improving energy conversion efficiency at the chip level and optimizing thermal management logic, manufacturers can eliminate redundant heat-dissipating components, reduce enclosure material specifications, and achieve substantial system-level BOM cost reductions while maintaining high-performance output.

For global electronics distributors and brand owners, low-cost, low-quality PCBA often carries hidden costs: customer complaints due to excessive device heat, e-commerce platform bans for safety hazards, and returns caused by poor compatibility.

AOVOLT’s core R&D team, composed of experienced engineers from Xiaomi, OPPO, and Vivo, leverages deep expertise in self-developed fast-charging chips and power management PCBA solutions. Through technological innovation, we solve these pain points, ensuring products deliver “Original Speed” while maintaining “No Overheating”, creating a differentiated competitive moat for B2B clients.

1. Escaping the “Low-Cost Trap”: Why Cheap PCBA Can Increase Overall BOM Costs

When selecting OEM/ODM partners, purely comparing PCBA unit prices is a common decision-making pitfall. Low-quality fast-charging solutions typically have low conversion efficiency (often below 85%), meaning a large portion of energy converts to heat. This triggers a series of escalating costs downstream.

Material Costs as Passive Compensation

To handle excessive heat, buyers are forced to use higher-rated, more expensive flame-retardant plastics or heat-resistant materials for the enclosure. Additionally, to prevent localized melting, large thermal pads or copper heat sinks are often required, increasing BOM cost rather than reducing it.

Design Limitations

High heat generation necessitates larger product sizes to allow better convection cooling. This prevents lightweight designs and directly increases packaging costs and airfreight expenses in cross-border logistics.

Quality Degradation and After-Sales Expenses

Power electronics follow the “10-degree rule”: every 10°C increase in operating temperature halves component life. High temperatures from low-quality solutions accelerate capacitor drying, resulting in a high annual failure rate (AFR).

Table 1: Hidden Cost Comparison – High-Performance vs. Traditional Low-Efficiency Solutions

| Dimension | High-Performance Solution (AOVOLT) | Traditional Low-Efficiency Solution | Impact on BOM/Operations |

|---|---|---|---|

| Conversion Efficiency | 92% - 94% (GaN/Synchronous Rectification) | 82% - 85% | Every 5% drop in efficiency increases heat by ~30% |

| Thermal Accessories | None or minimal thermal pads | Requires large thermal pads/copper sheets | Adds approx. $0.2 - $0.5 per unit |

| Enclosure Material | Standard UL94-V0 | High heat-resistant, thicker flame-retardant | Material cost increases 15%-25% |

| After-Sales Return Rate | < 0.3% | 2% - 5% | Directly erodes profit margins |

2. Efficiency Equals Money: Three Hidden Dimensions Where High-Performance Solutions Reduce BOM

Thanks to AOVOLT’s vertical integration—from chip design and PCBA development to mold production and finished product packaging—we can reduce system-level costs in three precise dimensions without sacrificing performance.

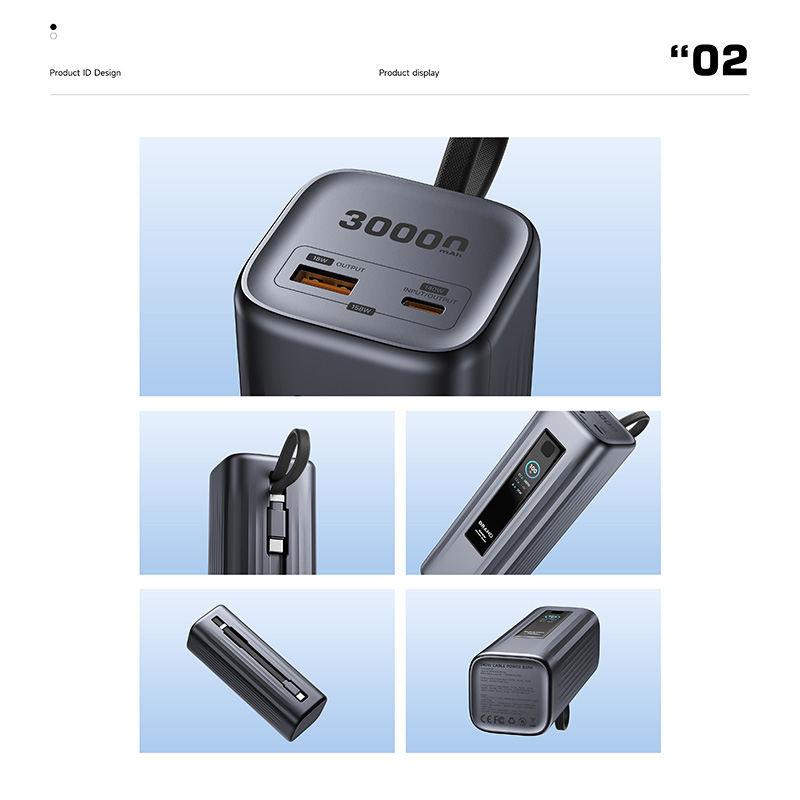

2.1 High Integration of Core Components

Traditional solutions require many peripheral components (RC absorption circuits, compensation circuits, etc.) to maintain voltage stability. AOVOLT’s self-developed fast-charging control chip integrates multiple power management functions onto a single die, reducing the number of MLCC capacitors and precision resistors on the PCBA.

Benefits:

-

Reduces SMT labor hours

-

Lowers material management costs (SKU handling)

-

Significantly reduces PCB size

2.2 Thermal Management Lightens Structural Components

When PCBA achieves “No Overheating”, thermal management no longer depends on expensive physical components.

Streamlined Design: Peak conversion efficiency keeps internal temperatures low, eliminating the need for bulky heat sinks.

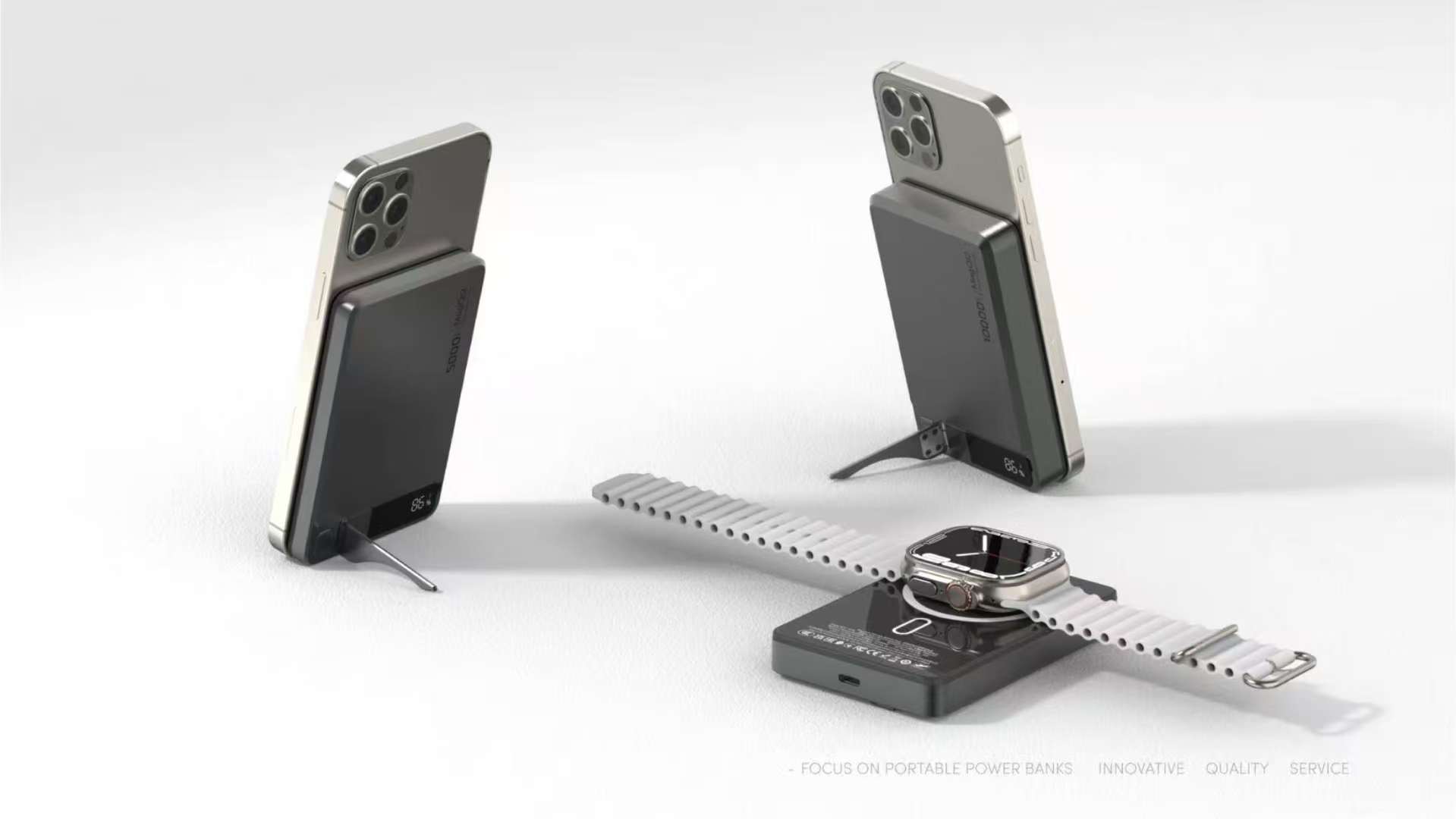

Space Optimization: Compact circuit layouts and patented enclosure designs reduce product volume by over 30% at the same power level. For large cross-border e-commerce sellers, this increases container load, reducing per-unit shipping costs.

2.3 Protocol Optimization Behind “Original Speed”

B2B buyers often face compatibility issues across different smartphone brands. AOVOLT engineers optimize the firmware, embedding a wide protocol library (PD3.1, PPS, QC, SCP, FCP, etc.) in the chip.

Value:

-

A single universal product serves most mobile devices worldwide

-

Reduces inventory risk and avoids the need for multiple SKUs

3. AOVOLT Technology Edge: “Dimensional Reduction” From Former Top-Tier Smartphone Engineers

In fast-charging, true technological advantage is often hidden in underlying logic. AOVOLT’s R&D roots lie deep in the smartphone supply chain. Our core team previously developed power management systems for Xiaomi, OPPO, and Vivo, enabling dual-end coordination between chargers and devices.

In-House Firmware Capabilities

Unlike many competitors using turnkey solutions, AOVOLT develops both fast-charging chips and firmware. This allows precise charging curve adjustments to solve transient response issues during high-power output, ensuring minimal voltage fluctuation and true Original Speed.

Advanced Thermal Management Logic

Engineers integrate smartphone-grade temperature control into chargers. Using high-frequency PWM control and synchronous rectification, AOVOLT PCBA maintains industry-low thermal loss even at full load.

Vertical Integration Efficiency

From chip design to finished product packaging, AOVOLT ensures every charger and power bank delivers Original Speed with No Overheating, guaranteeing safety and performance stability. Learn about high-performance fast chargers: OEM guide to raw speed and thermal safety.

4. In-Depth Technical Comparison: AOVOLT vs. Common Market Fast-Charging Solutions

The table below highlights the performance advantages of AOVOLT’s 65W GaN PCBA solution compared to typical market solutions.

Table 2: 65W GaN PCBA Performance Comparison

| Technical Metric | AOVOLT Solution (Self-Developed Chip + High-Frequency Architecture) | Market Common Solution (Generic Circuit) | B2B Procurement Impact |

|---|---|---|---|

| Peak Conversion Efficiency | 93.8% | 88.5% | Reduces heat energy loss significantly |

| Full-Load Enclosure Temp | 58°C - 62°C | 75°C - 82°C | Lower temperature improves safety and brand reputation |

| Output Ripple | < 80mV | 150mV - 200mV | Smaller ripple protects battery lifespan |

| Standby Power | < 30mW | > 75mW | Meets stricter EU Level VI efficiency |

| Mean Time Between Failures (MTBF) | 50,000 hours | 20,000 hours | Reduces repair and after-sales costs |

The ~5% efficiency advantage in AOVOLT solutions translates to nearly 40% less heat generation in power electronics, enabling extreme enclosure designs without thermal constraints.

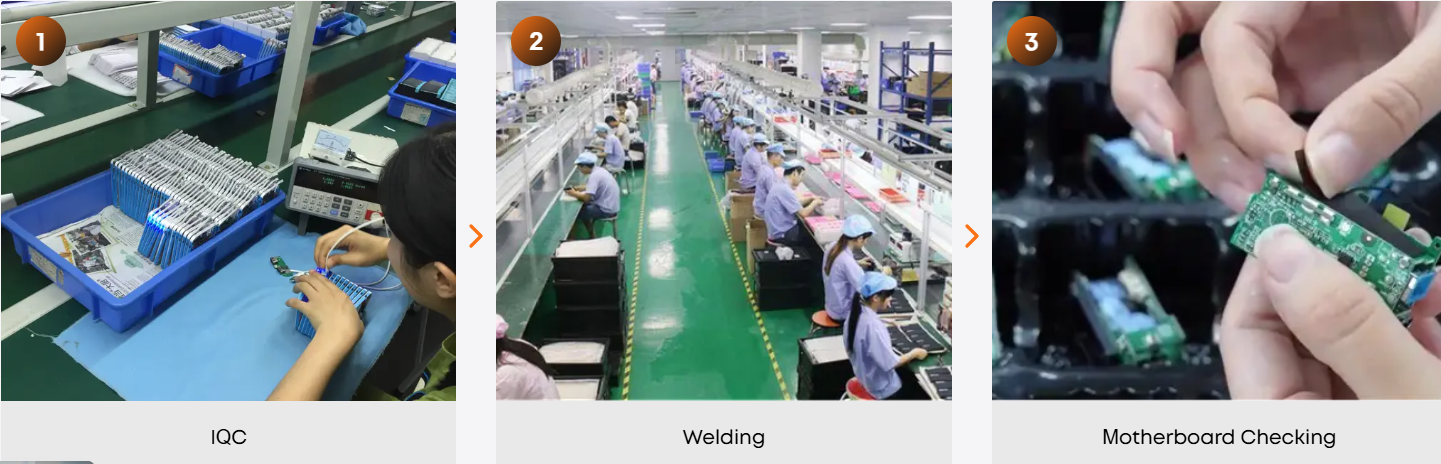

5. Global Compliance: The Last Line of Defense for Cross-Border Sellers and Brands

For large e-commerce sellers and global distributors, compliance is not optional—it’s a lifeline. Non-certified products or IP infringements can result in losses multiples higher than the BOM cost.

Comprehensive Certification Matrix:

-

ISO9001 certified factory

-

CE (EU), FCC (US), RoHS, IEC62133 (battery safety), UN38.3 (air transport safety)

Platform Ban Risk Mitigation:

-

All products feature patented enclosure designs

-

Differentiation improves brand premium and prevents store closure or bans

EMC Optimization:

-

Multi-stage filter circuits at the PCBA level ensure stability in complex electrical environments

-

Guarantees no interference with other devices and 100% pass local quality inspections

6. Conclusion: From Technology Leadership to Business Profitability

Choosing AOVOLT in the B2B fast-charging supply chain means selecting not just a supplier but a mature, large-factory-validated technical system.

Through in-house chips and vertical integration, “High Efficiency, Low Temperature, Safety” becomes measurable. For long-term growth, AOVOLT’s “Original Speed, No Overheating, Patented Design, Global Certifications” solution minimizes operational costs and boosts consumer repurchase rates.

Call to Action

Looking for a fast-charging OEM/ODM partner with top-tier R&D experience?

-

Custom PD3.1 & GaN PCBA Solutions: Tailored for global markets.

-

[Consult Our Technical Experts]: Receive customized BOM optimization and PCBA specifications.

-

[Download 2024 Product Catalog]: Explore our patented-design fast chargers and power banks.

-

[Request Sample Testing]: Experience high-performance No Overheating firsthand.

AOVOLT: Empowering your fast-charging business with large-factory-grade quality for the global market.

References: