In the global power supply market of 2026, achieving high wattage output is no longer a technical barrier. What truly defines a premium PD fast charging solution today is the ability to sustain 140W+ ultra-fast charging while delivering exceptional thermal control and OEM-level compatibility through deep optimization of the underlying PCBA architecture.

For global electronics wholesalers and top-tier cross-border eCommerce sellers, three major pain points continue to block brand premiumization:

-

Homogenized competition caused by off-the-shelf (public mold) products

-

Frequent customer complaints related to overheating

-

Hidden compliance risks on major platforms

AOVOLT’s core R&D team comes from leading smartphone brands such as Xiaomi, OPPO, and Vivo. Through self-developed fast-charging chips and power-management PCBA designs, we provide partners with “Original Speed” charging performance and enterprise-grade safety that exceed industry benchmarks—helping brands build a defensible technical moat in an increasingly crowded market.

PD Fast Charging Protocol Evolution: Why “Standard Versions” No Longer Work in 2026

With the full-scale adoption of PD 3.1 (EPR), single-voltage output solutions are officially obsolete. Modern B2B procurement teams must recognize that protocol coverage directly impacts return rates and brand reputation.

From PD 3.0 to PD 3.1 EPR: Entering the 240W Era

The PD 3.1 protocol not only increases maximum power delivery to 240W, but also introduces a far more sophisticated AVS (Adjustable Voltage Supply) mechanism.

AOVOLT’s solutions achieve millisecond-level bidirectional communication at the protocol layer, ensuring that high-performance laptops and workstations do not experience reboots or power throttling caused by handshake delays during charging.

The Truth Behind “Original Speed”: Full Compatibility with Private and Public Protocols

Many third-party chargers claim 65W output, yet only deliver 15W baseline power when charging specific smartphone brands.

Through precise PPS (Programmable Power Supply) tuning, AOVOLT engineers enable third-party accessories to replicate near-OEM current curves, unlocking charging speeds comparable to original manufacturer chargers. This capability is critical for brands targeting premium user experiences. Provide you with 140W GaN charger wholesale guide: PD 3.1, thermal control.

Table 1: PD 3.1 vs. Traditional Charging Solutions

| Technical Dimension | Traditional PD 3.0 Solution | AOVOLT PD 3.1 Advanced Solution | Business Value |

|---|---|---|---|

| Maximum Power | 100W | 140W–240W | Supports gaming laptops & workstations |

| Voltage Adjustment Precision | 20mV / step | 12.5mV / step (AVS) | Reduces cell heating, extends battery lifespan |

| Multi-Port Power Allocation | Fixed (disconnect-prone) | Dynamic Smart AI Allocation | Stable simultaneous charging |

| Protocol Coverage | Standard PD / QC | PD3.1 / PPS / FCP / SCP / AFC (Full) | Lower complaints, higher compatibility |

The Core of a Premium PD Charger: A Deep Dive into PCBA Architecture

A charger’s quality is determined not by its enclosure, but by the PCBA smaller than 50 cm² inside it. AOVOLT brings Tier-1 smartphone supply chain standards into OEM/ODM manufacturing.

Deep Integration of Self-Developed Chips and GaN Technology

Most market solutions rely on a “buy components + assemble” approach. AOVOLT focuses on in-house fast-charging ICs and power management systems, built on third-generation GaN (Gallium Nitride) semiconductors.

-

High integration: Over 20% reduction in peripheral components, lowering failure risk

-

High efficiency: Tested full-load efficiency exceeds 95%, converting less energy into heat

Extreme Miniaturization: EMI Control Under High Power Density

When power density exceeds 1.5W/cm³, EMI and ripple control become critical challenges.

AOVOLT uses advanced simulation tools during the design phase to optimize transformer winding structures and PCB routing.

-

Low ripple output: Maintained below 50mV (far better than the industry’s 100mV standard), protecting device BMS systems

-

Four-layer PCB stack-up: 2oz thick copper enhances overcurrent capacity and heat dissipation, ensuring electrical stability at high output

Solving the #1 Industry Problem: Thermal Management Under High-Wattage Fast Charging

In fast charging, speed is easy. Sustained high power with low surface temperature is not.

B2B buyers frequently face returns and platform safety reviews due to overheating issues. AOVOLT’s “No Overheating” commitment is not marketing—it is the result of a redesigned thermal management architecture.

Advanced Thermal Materials: From Silicone Pads to Graphene Composites

Beyond traditional heat sinks, AOVOLT adopts next-generation thermal solutions:

-

High-thermal-conductivity potting compound

Vacuum potting transfers heat from inductors and transformers directly to the enclosure, eliminating internal hot spots -

Graphene thermal coating

A graphene composite layer inside the housing improves heat radiation efficiency by over 15%

Intelligent Thermal Algorithms: Dynamic Frequency Control

AOVOLT’s proprietary power management firmware samples temperature 100 times per second.

-

Real-time monitoring: 3–5 NTC thermistors track temperatures of critical components

-

Linear frequency adjustment: Instead of abrupt power throttling at ~70°C, the system smoothly fine-tunes current by adjusting switching frequency

-

User-friendly surface temperature: After 2 hours of full-load output, enclosure temperature remains below international safety limits (typically 45°C–50°C)

Navigating Global Compliance: Certifications and B2B Risk Control

For brands selling on platforms such as Amazon and Lazada, missing certifications can result in customs rejection, heavy fines, or even store shutdowns.

Table 2: AOVOLT Compliance & Certification Framework

| Certification | Market Coverage | Core Evaluation Criteria | Business Impact |

|---|---|---|---|

| CE / RoHS | European Union | EMC, hazardous substance limits | Mandatory EU market access |

| FCC / UL | North America | RF interference, electrical insulation | Builds brand trust, reduces insurance risk |

| IEC 62368-1 | Global | AV & ICT equipment safety | Latest international safety standard (2026) |

| UN38.3 / MSDS | Global logistics | Lithium battery transport safety | Enables air & sea freight for power banks |

Rigorous Laboratory Testing Process

Every AOVOLT PD charger passes a “six-layer safety testing system”, including:

-

Burn-in testing: 100% full-load operation for over 4 hours to eliminate early failures

-

Surge testing: Simulates unstable voltage environments to protect user equipment

-

Salt spray testing: Ensures corrosion resistance during long-distance ocean shipping

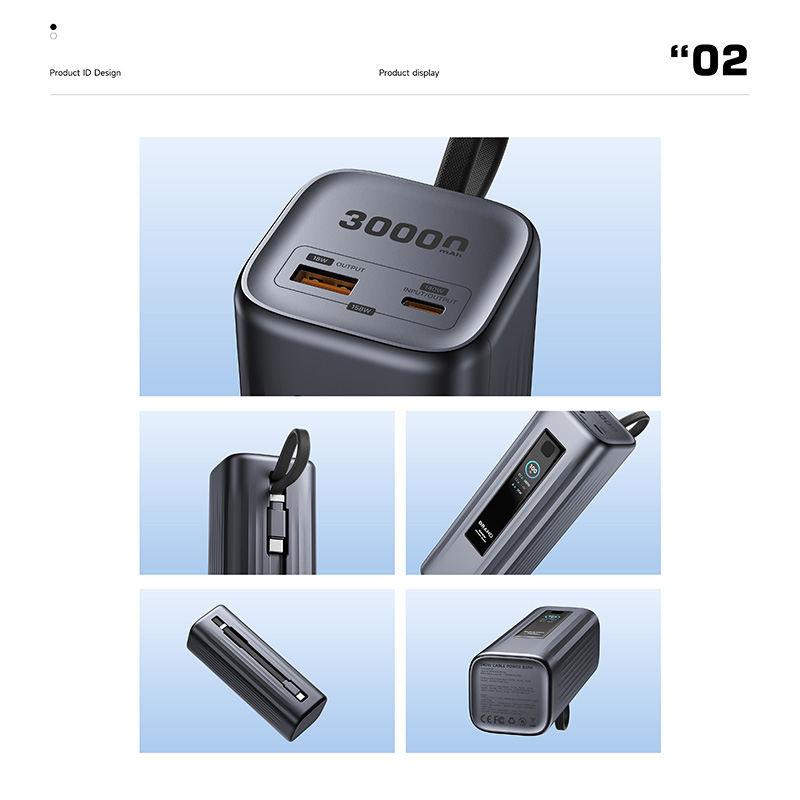

Differentiation Strategy: Patented Design and Customization

In a market flooded with look-alike products, unique design equals pricing power. AOVOLT offers deep OEM/ODM customization to help your products stand out on the shelf.

Private Mold Design & Patent Licensing to Avoid Takedown Risks

Public-mold products from small factories are highly vulnerable to design infringement claims.

-

Original industrial design (ID)

Our designers regularly release AOVOLT-exclusive designs and file global appearance patents -

Exclusivity agreements

For key clients, we offer regional exclusive sales rights for specific designs to protect market share

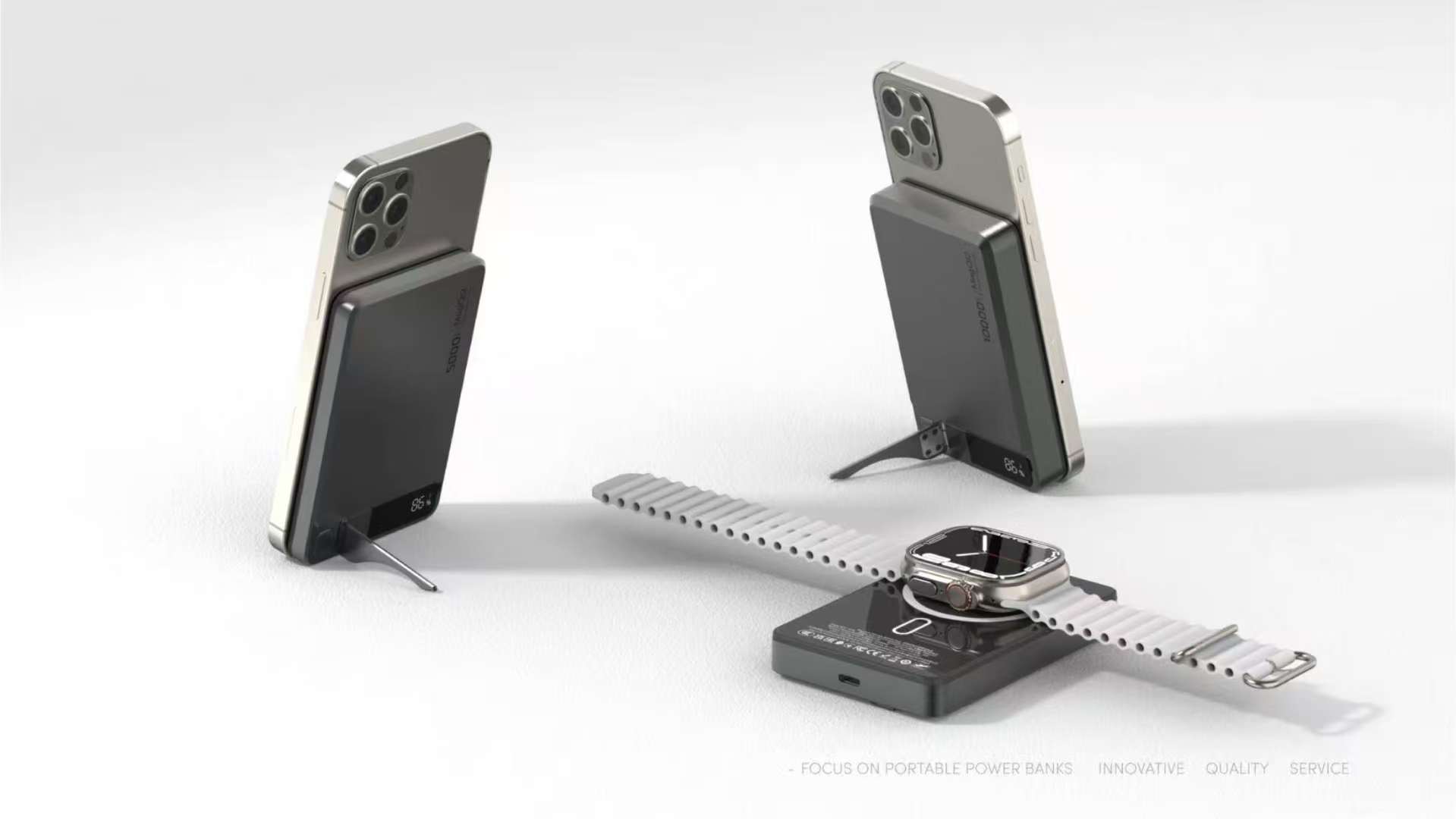

Customized Firmware: Flexible Power Allocation Logic

Different markets demand different priorities.

For example, brands targeting student users can deploy custom PCBA firmware that prioritizes tablets and smartwatches in multi-port charging scenarios.

-

UI/UX customization: Multi-language digital display interfaces for power banks

-

Brand identity: Laser engraving, boot-up logos, and deep OEM branding options

Conclusion: Choosing AOVOLT Means Choosing a Long-Term Technical Moat

In 2026, winning fast-charging brands need more than speed—they need stability, compliance, and differentiation.

With R&D talent from top smartphone brands, vertically integrated supply chains, and deep expertise in global certification standards, AOVOLT is not just your supplier—it is your external R&D department.

Why Choose AOVOLT?

-

OEM-grade R&D from Tier-1 smartphone ecosystems

-

Superior thermal control that reduces returns and boosts repeat purchases

-

Compliance without risk through full global certification coverage

-

No more sameness with patented designs that elevate brand value

References: