Choosing an OEM fast charger supplier isn’t about comparing price lists. It’s about assessing conversion efficiency at the power-management core and the supplier’s closed-loop thermal management capability. In the era of high power density, truly strong suppliers must integrate capabilities from chip-level protocol optimization through vertical manufacturing of finished products—ensuring “original manufacturer speeds” while maintaining cool, stable operation over long-term use.

For B2B buyers, cross-border eCommerce leaders, and brand owners, low-quality OEM products don’t just cause higher return rates—they damage brand reputation and introduce platform compliance risks.

AOVOLT’s core R&D team is composed of senior engineers from leading smartphone brands such as Xiaomi, OPPO, and Vivo. With in-house fast-charging chip development and PCBA design, we’ve built defensible technical barriers against the industry’s long-standing heat issues. Through vertically integrated manufacturing, we ensure batch-to-batch stability—helping partners build a technical moat in a highly commoditized market.

Pain Point Analysis

Why Most OEM Fast Chargers Fail to Balance “Speed” and “Temperature”

In today’s fast-charging market, many B2B buyers face a paradox: to chase higher output power (65W, 100W, even 140W), products often become uncomfortably hot within 15 minutes, triggering thermal throttling and causing charging power to drop sharply.

This “fast charging that isn’t actually fast” typically stems from three technical shortcomings:

1. Limitations of Generic Reference Designs

Most second- and third-tier suppliers lack chip-level development capability and rely on off-the-shelf PCBA reference designs. Without deep tuning, conversion efficiency usually sits at 85%–88%, meaning 12%–15% of energy is converted directly into heat trapped inside a compact enclosure.

2. Outdated Power Topologies

To reduce costs, many suppliers still use traditional silicon (Si) power devices instead of high-frequency, low-loss gallium nitride (GaN) technology. Even when labeled as GaN, poor gate-drive and circuit design prevent GaN from delivering its true efficiency advantages.

3. Simplistic Compatibility Logic

Low-quality chargers often rely on crude cut-off/restart logic for multi-port power allocation and fail to accurately recognize proprietary fast-charging protocols. This mismatch between the charging curve and battery demand causes unnecessary electrochemical heat buildup.

Data Comparison

How Conversion Efficiency Impacts Heat Generation

| Conversion Efficiency | Power Loss at 65W Load (Heat) | Estimated Internal Heat (1 Hour) | Max Case Temperature (25°C / 77°F Ambient) |

|---|---|---|---|

| 85% (Low-quality reference design) | 11.47 W | Extremely high; power derating required | >65°C (149°F) — too hot to touch |

| 88% (Standard OEM) | 8.86 W | High; noticeable case temperature rise | 58°C–62°C (136°F–144°F) |

| 93% (AOVOLT solution) | 4.89 W | Low; supports sustained full load | 45°C–50°C (113°F–122°F) |

The Hidden Damage of Homogeneous Competition

On Amazon, Lazada, or offline distribution channels, if your product shares the same generic housing as thousands of other sellers, you’re inevitably dragged into a price war. Worse, this homogeneity hides serious operational risks:

IP Infringement & Account Suspension

Many low-cost suppliers directly copy the designs of top-tier brands. Once listed on global platforms, B2B buyers face a high risk of design patent infringement claims, leading to inventory freezes and store shutdowns.

Safety & Compliance Gaps

To save a few cents, some factories omit EMI shielding or use low-grade capacitors. While initial costs drop, such products often fail CE, FCC, or UL spot checks—a ticking compliance time bomb for cross-border sellers.

One-Star Review Killers

The most common negative reviews for fast chargers are “gets too hot” or “failed after a few months.” Without differentiation and technical credibility, brands struggle to build long-term customer loyalty.

Thanks to AOVOLT’s vertical integration—from fast-charging chip design and PCBA development to tooling and final packaging—we ensure every charger and power bank delivers original-speed performance while staying cool, with outstanding safety and stability.

The Solution

Four Core Dimensions of a High-Performance OEM Fast Charger Supplier

For B2B procurement, supplier evaluation must shift from simple “capacity” to R&D depth and quality certainty. AOVOLT redefines premium OEM/ODM standards across four dimensions:

1. R&D at the Source

Engineers from Tier-One Smartphone Brands

Why does it matter if OEM engineers come from original phone manufacturers? Because fast charging is not just about current—it’s a complex protocol handshake.

-

Deep Protocol Optimization: Our core team understands both proprietary protocols (e.g., SuperVOOC, Mi Turbo Charge) and public standards (PD 3.1, PPS).

-

Original Speed: Unlike suppliers that only maintain baseline PD output, AOVOLT solutions precisely match device charging curves—sustaining full power without drop-offs.

2. Core Technology

In-House Fast-Charging Chips & High-Efficiency PCBA Design

Control over core technology defines performance ceilings. AOVOLT avoids third-party generic solutions by developing proprietary chips for precise current control.

-

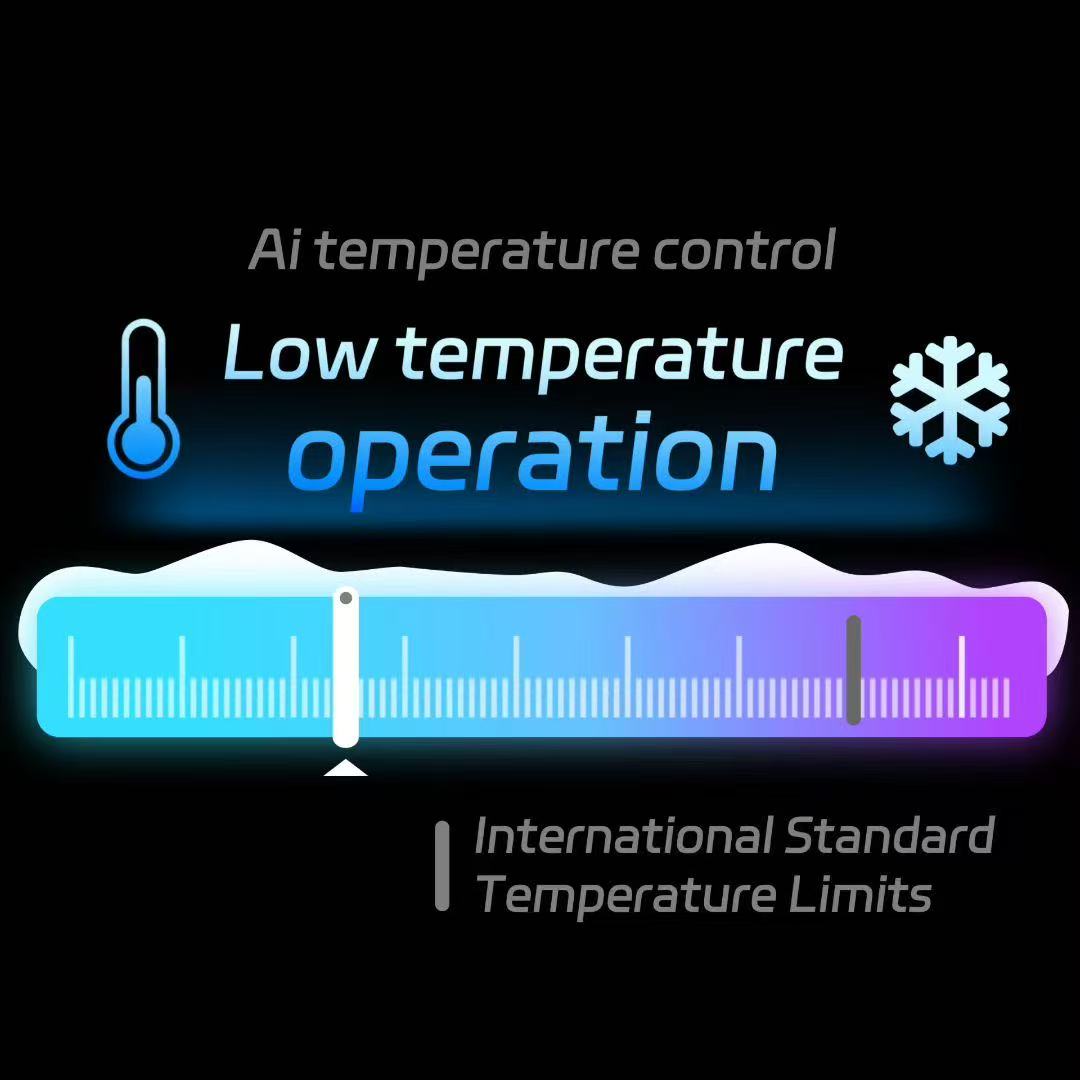

Chip-Level Thermal Algorithms: Built-in intelligent PWM dynamically adjusts switching frequency based on real-time temperature—reducing magnetic and switching losses at the source.

-

Advanced GaN Integration: Using third-generation semiconductors with proprietary thermal topologies, we reduce size by 30% while pushing efficiency beyond 93%.

3. Market Barriers

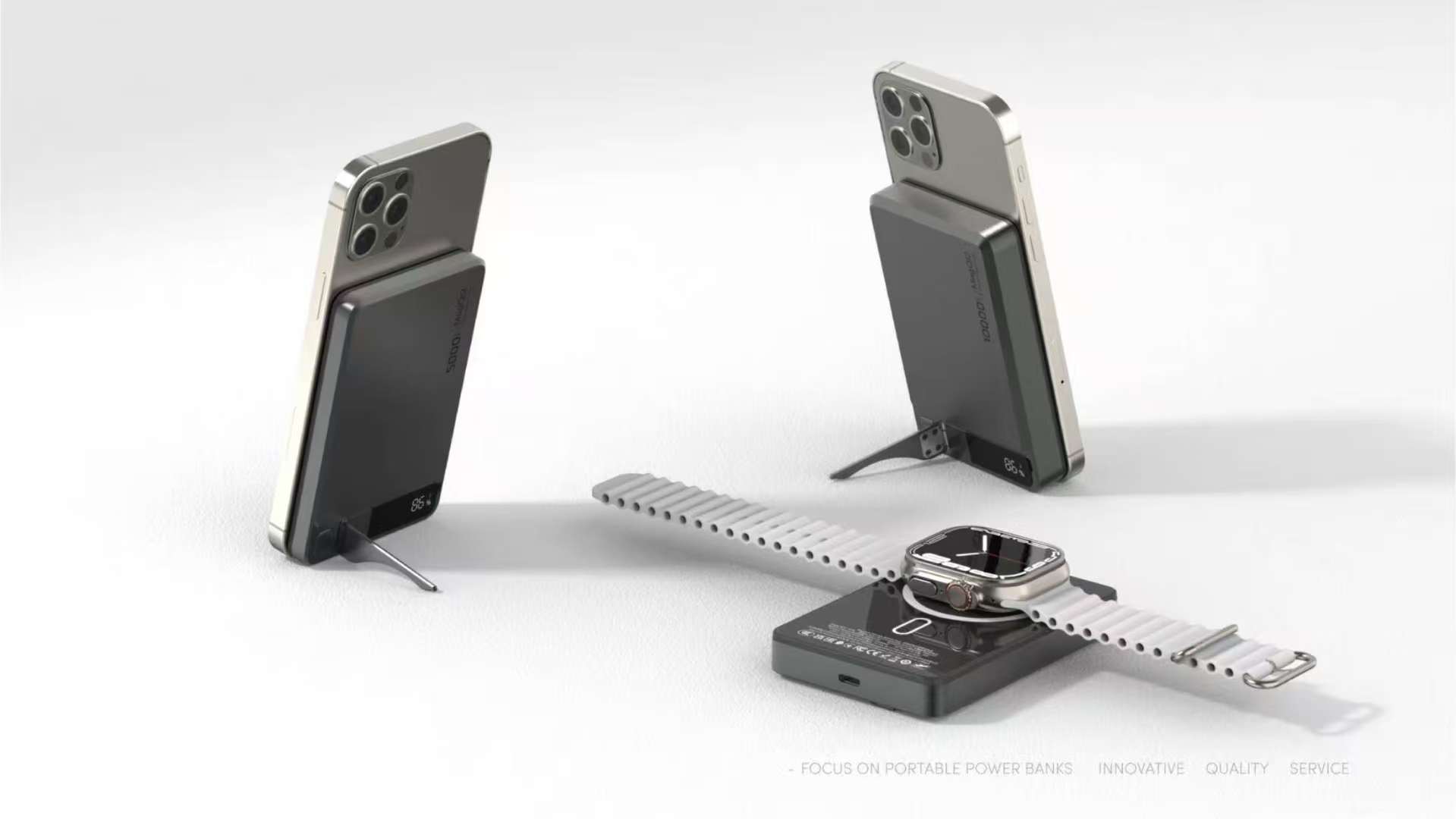

Patented Designs & Differentiated Products

On global marketplaces, visual uniqueness directly impacts click-through rates and risk mitigation.

-

Zero Takedown Risk: AOVOLT insists on private tooling. Every product carries independent design patents, protecting B2B customers from infringement-related delistings.

-

Industrial Design Meets Practicality: Customization spans color, materials (e.g., V0 flame-retardant PC), and plug standards—tailored for US, EU, UK, and AU markets.

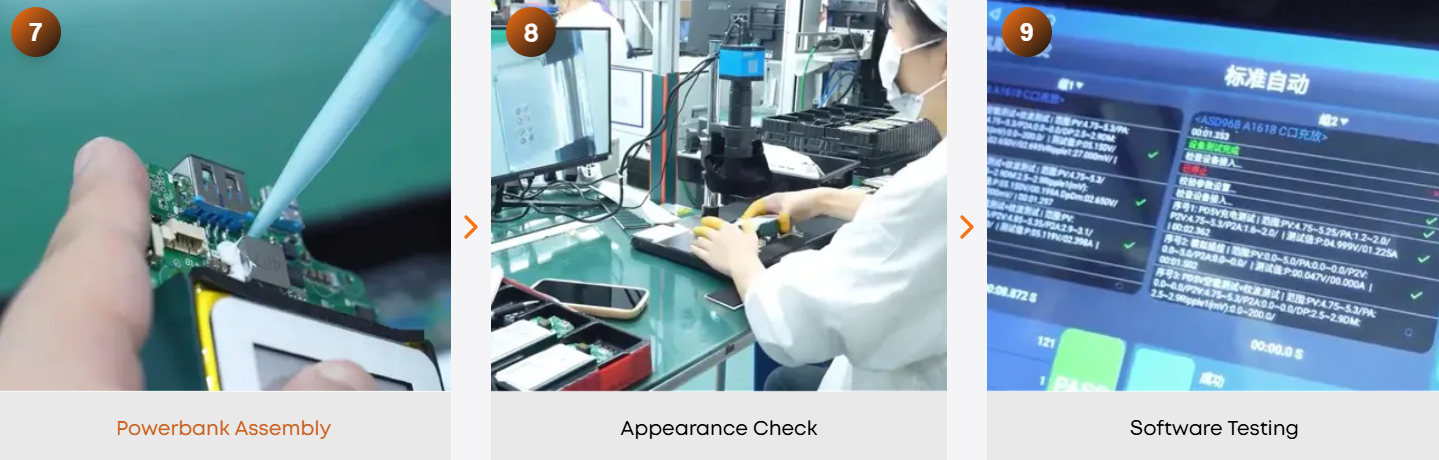

4. Quality Control Loop

ISO 9001 Factories & Vertically Integrated Manufacturing

“Vertical integration” isn’t a slogan—it’s total supply-chain control.

-

End-to-End Inspection: From SMT and ultrasonic assembly to aging tests, all processes are completed in AOVOLT-owned facilities.

-

Stability Assurance: Every unit undergoes 4–8 hours of full-load aging, ensuring stable performance even under extreme heat and keeping defect rates below 0.1%.

Technical Comparison

AOVOLT “Original Speed” Solution vs. Standard Market OEMs

| Metric | AOVOLT Intelligent Fast-Charge | Typical Market OEM | Buyer Benefit |

|---|---|---|---|

| Protocol Support | PD 3.1 / PPS / All major proprietary protocols | Basic PD 3.0 / QC 3.0 | Broad device compatibility |

| Thermal Performance | 45°C–50°C (cool, no throttling) | 60°C–68°C (hot, throttles) | Longer lifespan, fewer complaints |

| Design Uniqueness | Exclusive patented tooling | Generic public mold | IP safety, premium pricing |

| Safety Protection | Six-layer chip-level intelligent protection | Basic triple protection | Lower after-sales & legal risk |

Global Certifications & Compliance

The “Master Key” for B2B Risk Control

For cross-border distributors and brand owners, certification is the only passport to market entry. Uncertified products are highly vulnerable at customs, on platforms, and in legal disputes.

AOVOLT products strictly comply with global standards and carry:

-

US & EU Market Access: CE, RoHS, FCC—ensuring legal sales and environmental compliance.

-

Safety Testing: IEC 62133 (for power bank cells) and UL-grade testing, proving physical safety under extreme conditions.

-

Air Transport Compliance: MSDS and UN38.3—essential for global logistics and air freight.

Our Commitment: Customers avoid high certification costs and long lead times. AOVOLT’s established compliance framework empowers partners to launch quickly and profitably.

Conclusion

In the fiercely competitive fast-charging and power-management market, choosing a supplier with in-house chip development and tier-one R&D DNA is key to long-term brand success.

AOVOLT delivers more than hardware—we provide a complete competitive solution combining high performance, low-temperature safety, differentiated design, and global compliance.

Thanks to AOVOLT’s vertical integration—from fast-charging chip design and PCBA development to tooling and final packaging—we ensure every charger and power bank achieves original manufacturer speeds while staying cool, safe, and stable.

Want AOVOLT’s 2026 fast-charging product catalog and detailed technical white papers?

Contact our technical marketing experts today to customize your OEM/ODM solution—and start the next chapter of high-quality fast charging.

References:

USB Power Delivery 3.1 Specification — USB-IF

GaN vs Silicon MOSFET: Comparison Report — ON Semiconductor / TI