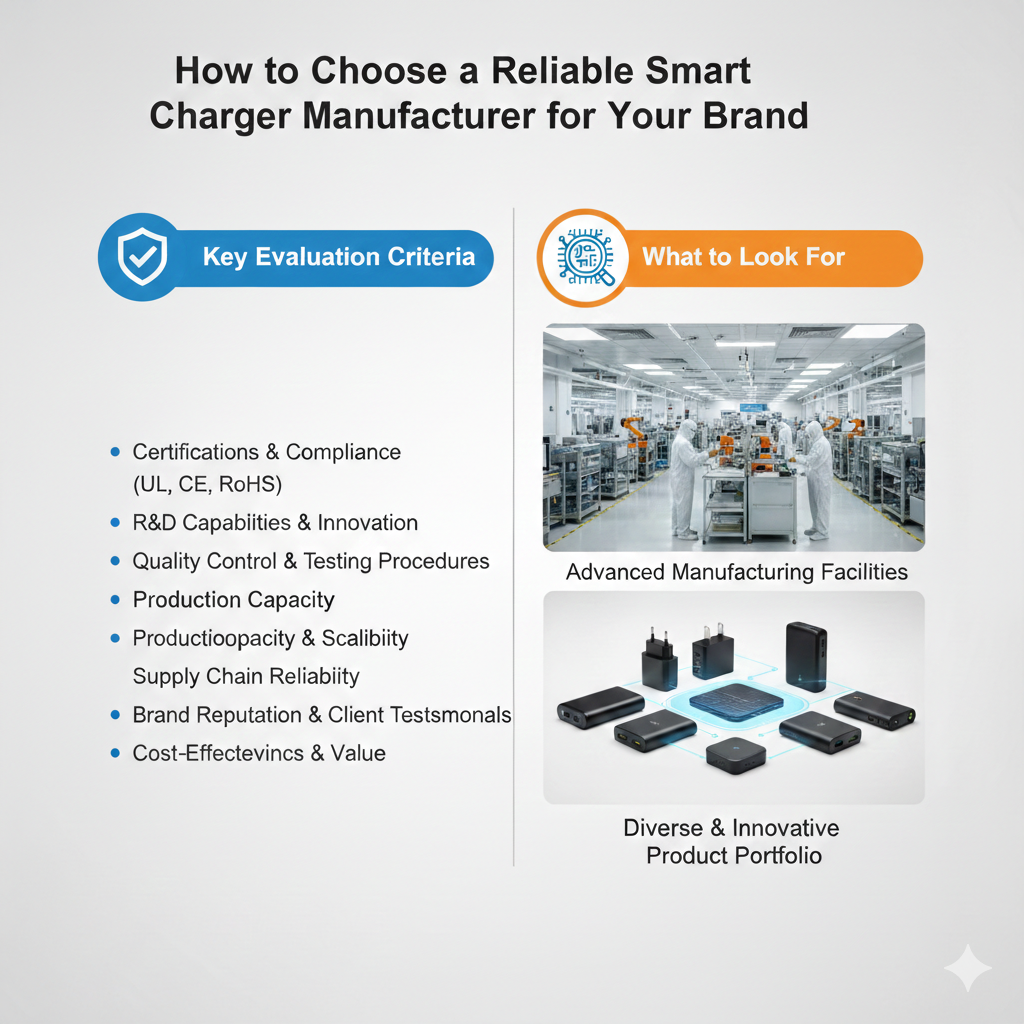

How to Choose a Reliable Smart Charger Manufacturer for Your Brand

Why the Right Partner Matters More Than Ever

In 2026, the difference between a successful charger brand and an average one lies in the supply chain.

A reliable smart charger manufacturer is not just a supplier; it’s a strategic partner that translates technology, compliance, and design into market trust. The rise of AI-integrated and GaN-powered charging solutions has raised industry standards for both safety and efficiency.

Let’s explore how you can choose the right manufacturer and what criteria define a truly reliable OEM partner.

1. Understanding the Smart Charger Manufacturing Landscape

From Traditional to Intelligent Production

The shift from basic charging adapters to AI-controlled GaN chargers has transformed how factories operate. Leading smart charger manufacturers today combine three capabilities:

-

GaN Power Conversion: Higher efficiency (94–96%) and lower thermal output.

-

AI Power Management: Adaptive voltage and multi-device recognition.

-

Certified Production: CE, FCC, UL and PSE compliance as a baseline.

According to the International Energy Agency, GaN-based power systems can cut global energy loss by up to 35%, making sustainability a key OEM selection factor.

2. Technical Capabilities and Production Scale

What Separates Top-Tier Factories from Assemblers

A credible smart charger manufacturer maintains an end-to-end supply chain:

| Capability | What to Check | Why It Matters |

|---|---|---|

| PCB Design & R&D | In-house design team, firmware updates | Ensures innovation & long-term support |

| SMT Production Lines | 10 000+ daily output capacity | Supports bulk OEM orders |

| Aging & Safety Testing | 500 + cycle stress tests | Reduces return rate & field failures |

| Chip Suppliers | Navitas / Infineon / PI | Guarantees component reliability |

Factories like ESCCharge integrate AI firmware and GaN semiconductors on the same assembly line, shortening prototyping cycles by 20%.

3. Certifications and Compliance

The Non-Negotiables

Before signing any OEM contract, ensure your manufacturer complies with:

-

UL 62368-1 — Safety standard for IT equipment.

-

CE / FCC / PSE / CCC — Regional export requirements.

-

UN38.3 / RoHS / REACH — Transport and environmental compliance.

Lack of certification can delay customs clearance and invalidate insurance claims.

A truly reliable smart charger manufacturer provides traceable batch reports and 3rd-party test certificates for every order.

4. Customization and OEM Flexibility

From Branding to Firmware Integration

Modern brands seek more than a logo print. They want firmware control, color design, and market-specific certifications.

A good manufacturer should offer:

-

Private-label molding and color schemes

-

Custom output range (20 W – 200 W)

-

Multi-protocol support (PD 3.1, PPS, QC 5.0)

-

Firmware branding or OTA update capability

These elements let OEM buyers build differentiated products for niche markets — from travel adapters to industrial fast chargers.

5. Evaluating Reliability through Testing and Quality Control

Numbers That Speak for Trust

Ask for test bench data before you commit. Typical benchmarks include:

| Test Item | Standard | Result (Top Factories) |

|---|---|---|

| Aging Test | 8 hours continuous load | Passed 99.8% |

| Temperature Cycle | –20 °C to 80 °C | Stable output voltage |

| Drop Test | 1.2 m height | No case fracture |

| EMC Interference | CE Class B | Below 3 dB limit |

These data-driven indicators help buyers avoid “spec sheet only” factories.

6. Communication and After-Sales Support

The Invisible Advantage

Responsive technical teams and structured project management differentiate top manufacturers from resellers.

Key traits include:

-

Bilingual project managers and 24-hour response service.

-

Regular production status updates with photos and reports.

-

Warranty terms and failure analysis support within 48 hours.

A professional smart charger manufacturer treats after-sales service as part of the OEM value chain.

7. Long-Term Sustainability and Ethical Sourcing

Beyond Profit — Toward Responsibility

With ESG compliance becoming a procurement priority, buyers should confirm their partners:

-

Use recyclable aluminum or bioplastic housings.

-

Follow ISO 14001 environmental standards.

-

Provide carbon-footprint reporting for bulk orders.

The World Economic Forum predicts that “green manufacturing compliance will be a decisive factor in electronic exports by 2027.”

8. Practical Checklist Before Signing an OEM Contract

| Step | Action | Purpose |

|---|---|---|

| 1 | Audit production line (video or on-site) | Verify real capacity |

| 2 | Review certificates and test reports | Confirm compliance |

| 3 | Request 3D design mock-up | Validate branding fit |

| 4 | Sign NDA + OEM agreement | Protect IP and design rights |

| 5 | Approve sample batch | Finalize mass production criteria |

Conclusion: Your Smart Charger Partner Defines Your Brand

A successful charger business in 2026 requires more than competitive pricing — it demands a trusted smart charger manufacturer who can combine engineering depth, OEM flexibility, and compliance expertise.

ESCCharge stands as a global partner offering GaN PD solutions, AI charging platforms, and custom manufacturing support for brands worldwide.

Explore our smart charger OEM capabilities at ESCCharge Official Website and build your next generation of intelligent charging solutions.